Bao Gang

University of Ruse “Angel Kanchev”, Bulgaria

Pavel Vitliemov

ORCID iD: 0000-0002-1747-7994

University of Ruse “Angel Kanchev”, Bulgaria

https://doi.org/10.53656/igc-2024.19

Pages 172-185

Abstract. The manufacturing industry with the deepening of the reduction principle of circular economy, not only pursue the maximum utilization of resources, but also pursue the maximum profit. However, at present, manufacturing enterprises are faced with many challenges such as how to allocate limited resources efficiently and reasonably in real time, waste of resources caused by low cost-effectiveness product excess, and low profits. Enterprises need to strengthen cost management, allocate limited resources efficiently and reasonably, and improve profitability in order to cope with the increasingly complex competitive market. Here, the research in this area becomes very important. This paper proposes a new approach to build an intelligent decision-making process, especially in terms of efficient and rational allocation of limited resources and profitability. Emphasize the importance of efficient and rational allocation of limited resources and profitability decision-making, so the purpose of research is to allocate limited resources efficiently and rationally, and make decisions according to market demand in order to maximize profits. The research in this paper is inspired by the economic concept of production possibility frontier. From the current common economic concept of studying the production possibility frontier curve model of two products is extended to the production possibility frontier of more than two products. Moreover, the production possibility frontier of various products is combined with the linear programming model to find the maximum profit and the production possibility combination of products. The whole process describes the basic steps and modules needed to efficiently and rationally allocate limited resources and establish a profitability decision process. The specific contents include first determining variables and constants, then establishing models and setting the constraint conditions, and finally using LINGO software to solve the model to get the ideal maximum profit and the quantity of various products in the product production possibility combination. The advantage of this decision system is to help enterprises to maximize profits, improve the utilization rate of limited resources, and efficiently and reasonably allocate limited resources to meet the market demand.

Keywords: production possibility frontier; limited resources; linear programming model; profitability; efficiency; manufacturing organization

JEL: L10, L19

- Introduction

The manufacturing industry with the rapid development, market demand and production requirements are constantly changing in real time, a series of resource allocation and production decision-making problems often appear in the development of manufacturing industry, which is related to the income of manufacturing enterprises. If resources are properly allocated and produced, the enterprise will obtain the maximum profit with reasonable resource consumption. If resources are improperly allocated and too many products with low cost performance are produced, the products will be unmarketable and resources will be wasted. This is not only a resource allocation problem, but a production decision problem. In order to cope with the increasingly competitive market environment, circular economy has been paid more and more attention in the manufacturing industry. Circular economy is the core of efficient utilization and recycling of resources. Based on the 3R principles of reduction, reuse and recycle, and characterized by low consumption, low emission and high efficiency, it is essentially a green, low-carbon and sustainable economic development model (Blachly et al., 2024).

The circular economy has a positive impact on manufacturing enterprises and can help enterprises promote sustainable development goals, playing a role in reducing resource consumption, promoting environmental protection and meeting market demand, and has a competitive advantage in the market. However, the circular economy has also exposed a lot of issues in the actual production decision application, such as high input cost in the early stage, long period of effectiveness, poor operability, and lack of key technologies and so on (Aigner et al., 2023). Manufacturing enterprises face the challenges brought by the application of circular economy in the manufacturing industry. In order to obtain the maximum profit with low cost and high efficiency, we can start from the production source, save resource input or maximize the utilization efficiency of limited resources, do not waste resources, and make every resource to obtain the highest value return, following the reduction principle of circular economy. In this process, we combine the market supply and marketing price demand and cost control. At the same time, decision-making production is guided by the maximum profit that manufacturing enterprises can obtain (Asmild et al., 2024).

This paper proposes a new approach to building smart decision-making processes, especially in terms of efficient and rational allocation of limited resources and profitability. Objective to solve the issue of limited resources to produce N (N>=2) different types of products, how to efficiently and reasonably allocate resources to find the optimal product production combination to help enterprises obtain maximum profits. Inspired and supported by the production possibility frontier model of two kinds of products, we try to deduce the production possibility frontier model of N (N>=2) different types of products, and construct a linear programming model to find the maximum profit of all points located on the production possibility frontier model of N kinds of products to screen the optimal product production combination. In order to realize the efficiency and rapidness of the specific screening process, we use Lingo software to quickly calculate the constructed linear programming model and qualification conditions to obtain the maximum profit and the optimal product production combination (Aryal et al., 2023). This paper describes the basic steps and modules needed to efficiently and rationally allocate limited resources and establish a profitability decision process. The advantage of this decision system is that it can help enterprises to maximize profits, improve the utilization rate of limited resources, and efficiently and reasonably allocate limited resources to meet the market demand.

2. Theoretical background

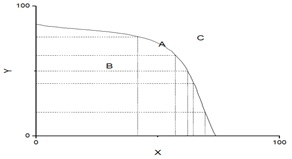

We mentioned earlier that circular economy mainly follows the 3R principle which are Reduction, Reuse and Recycle, the reduction principle is the first step of circular economy, it is also the most important part. The principle of reduction is to require less resource inputs and the use of less raw materials, which is to improve the utilization efficiency of resources in order to achieve the established production goals (Molhova & Biolcheva, 2023; Trubins, 2023). However, in actual production, there are often shortages or limited use of resources or raw materials due to various reasons. This process involves an economic concept – production possibility frontier. The production possibility frontier curve is used to illustrate and describe the maximum possible production combination under limited resources and technologies, and can be used to select various product production combinations (Pang et al., 2024; Burggräf et al., 2020). The production possibility frontier curve is composed of points, each of which represents a product production combination (product production combinations are combinations of different kinds of products, and the common feature of these combinations is the use of the same resources or raw materials). The production possibility frontier can be used to illustrate the problem of potential and excess. Any point inside the production possibility curve means that the production potential has not been fully developed and the resources have not been fully utilized (Elbasheer et al., 2022; Valero-Carreras et al., 2021). Any point outside the production possibility curve is a production demand that cannot be met by existing resources and technical conditions; The point located on the production possibility frontier curve is the point with the highest resource allocation efficiency (the most efficient and reasonable resource utilization). All the points on the production possibility frontier curve are the points with the highest resource allocation, and a point represents a product production combination, as shown below on Figure 1:

Figure 1. Production Possibility Frontier Curves for Two Products

But not every product production combination can help the enterprise to obtain the maximum profit. Therefore, we need to have a choice of production decisions. Here, we need to build a linear programming model to obtain the maximum profit. We take the enterprise to obtain the maximum profit as the decision orientation, and select the optimal product production combination from all the product production combinations on the production possibility frontier curve. The optimal product production combination has the characteristics of efficient and reasonable resource allocation and maximum profit (Sterev et al., 2020; Yang et al., 2022). The existing literature mainly focuses on the possibility frontier curve and opportunity cost of the production of two kinds of commodities. At the same time, most of the existing literatures refer to the existence of production possibility frontier to prove the existence of scarcity, and do not consider the quick and efficient solution to calculate the maximum profit that manufacturing enterprises can obtain under the condition of limited resource allocation of more than two products or more products. However, we extend the multi-product resource allocation model based on the production possibility frontier. Specifically speaking, in actual production, limited resources or raw materials may be allocated to produce more than two different products, and the calculation process of such allocation is complicated, time-consuming and costly, and there are a lot of human factors and poor accuracy (Li et al., 2022; Sterev, 2023; Yan et al., 2023). Therefore, we will use the software LINGO to construct a linear programming model to obtain the maximum profit. The characteristics of LLINGO are simple, practical, efficient and fast to calculate the production quantity of each product of the optimal product production combination and the maximum profit that can be obtained by the optimal product production combination (Biolcheva & Sterev, 2024; Zhou et al., 2021).

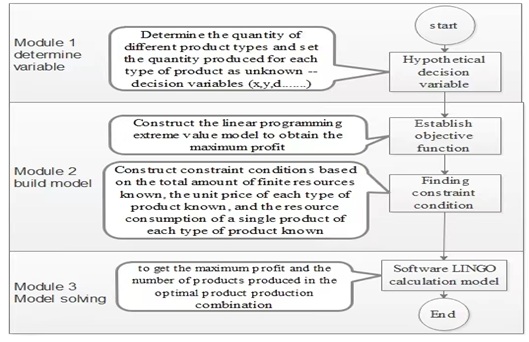

The process consists of three main modules:

– Module 1: Determine variables

Hypothetical decision variable: This process is to determine the quantity of different product types and set the quantity produced for each type of product as unknown decision variables(x.y.d…..)

– Module 2: Build model

This module is mainly to establish the objective function and find the constraint conditions.Construct the linear programming extreme value model to obtain the maximum profit. At the same time, construct constraint conditions based on the total amount of finite resources known, the profit of one product of each type of product known, and the resource consumption of a single product of each type of product known.

– Module 3: Model solving by using software LINGO

Calculate the constructed linear programming model in LINGO software to find the maximum profit and the production quantity of different products in the optimal product production combination, his flow chart is as follows on Figure 2:

Figure 2. Flow module operation diagram

According to the flow chart, the objective functions and constraints of various types of product combinations are established, and the results are obtained by running on the software LINGO.

3. Concept of proposed approach in terms of profitability for N types of products

3.1. Construction of linear programming model

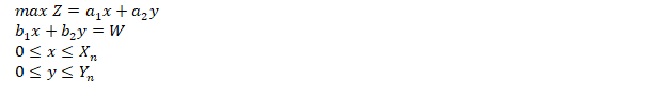

Under the condition of given resources and technology or limited resources, all points on the production possibility frontier model curve of two products represent different quantity combinations of the two products, but not every combination will make the enterprise obtain the maximum profit. Therefore, from the perspective of profitability, building a model first requires determining variables and constants then the linear programming model of two products is constructed to find the maximum profit value of all quantity combinations on the production possibility frontier curve, as follows:

Equation 1. The linear programming model and constraints of two different types of products

Here, max Z is the maximum profit value; variable x and variable y are the total production quantities of the two types of products respectively; a1 and a2 are the profit of one product of the two types of products respectively ; b1 and b2 are the resource consumption of a single product of the two types of products respectively; W is the total resources; a1, a2, b1, b2, W are constants; ![]() is the maximum quantity of x produced with all resources

is the maximum quantity of x produced with all resources ![]() ), and

), and ![]() is the maximum quantity of y produced with all resources (

is the maximum quantity of y produced with all resources (![]() ).

).

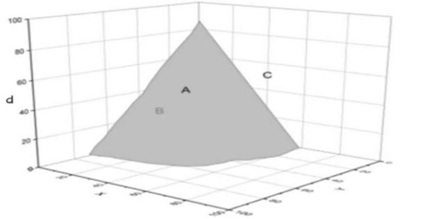

The maximum profit value of the quantity combination on the production possibility frontier of two products is a common analysis and research situation at present. When using limited resources and technology to produce 3 different types of products, the research situation will become more complex, the research object will change from two-dimensional to three-dimensional, and the production possibility boundary model curve will change from a curve in the plane to a surface in three-dimensional space, as shown in the Figure 3 below:

Figure 3. Production possibility frontier surface for three products

At this time, d is the third product variable, it is necessary to add the maximum possible profit of total quantity of the third product variable into the linear programming model (![]() , the constant

, the constant ![]() is the profit of one product of the third type of product ; meanwhile;It is also necessary to add thee total possible resource consumption of total quantity of the third product variable

is the profit of one product of the third type of product ; meanwhile;It is also necessary to add thee total possible resource consumption of total quantity of the third product variable ![]() , the constant

, the constant ![]() is the resource consumption of one product of the third type of product.

is the resource consumption of one product of the third type of product. ![]() is the maximum quantity of d produced with all resources

is the maximum quantity of d produced with all resources ![]() ), The model is as follows:

), The model is as follows:

Equation 2. The linear programming model and constraints of three different types of products

Similarly and so on, as the variety of products that need to be produced increases. The production possibility boundary model of multiple products will enter the K-dimensional space, even the Euclidean space, but in this process, when the production plan adds a type of product, it only needs to increase the relevant variable、the total maximum possible profit and the total possible resource consumption of total quantity of this variable and the maximum quantity of this variable produced with all resources in the linear programming model and constraints. Therefore, the linear programming model and constraints for finding the maximum profit of producing N different types of products are as follows:

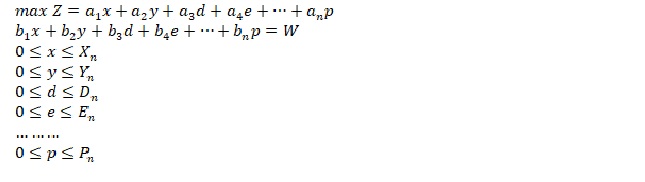

Equation 3. The linear programming model and constraints of N different types of products

the constant W is the total resources; a1, a2, a3, a4…. and are constants, they represent the profit of one product of different types of products respectively; b1, b2, b3, b4…bn are constants, they represent the resource consumption of one product of different products respectively; x, y, d, e…p are variables, they are the production quantities of different products and must be greater than or equal to zero; ![]() ,

, ![]() ,

, ![]() ,

, ![]() ….

…. ![]() . respectively are the maximum production quantities of a type of product(

. respectively are the maximum production quantities of a type of product(![]() ,

, ![]() ,

, ![]() ,

, ![]() ,

, ![]() .

.

3.2. LINGO software solution

In the deduction of the linear programming model of the production possibility frontier of N products, it is necessary to calculate the maximum profit value in all quantity combinations and the production quantity of each of the N products in the quantity combination that obtains the maximum profit value. This will be a very complicated process. In order to simplify the complex problem, we will use the software LINGO to solve the maximum profit value max Z of the linear programming model of the production possibility frontier of N products and the production quantity of each product in the quantity combination that obtains the maximum profit value. M and V stand for the total profit and the total resource consumption made by more different types of products respectively. The specific process is as follows:

– Step 1: LINGO software executes instructions

We will build linear programming models directly in LINGO software using limited resources to obtain the total maximum profit value and the quantity of each product produced in a combination of products. Table 1 shows the models construction process:

Table 1. Executes instructions of the linear programming model and constraints of N types of products

| 1 | MaxZ=a1*x+a2*y+a3*d+M+an*p; |

| 2 | b1*x+b2*y+b3*d+V+bn*p=W; |

| 3 | x<=; |

| 4 | y<=; |

| 5 | d<=; |

| 6 | …..; |

| 7 | p<=; |

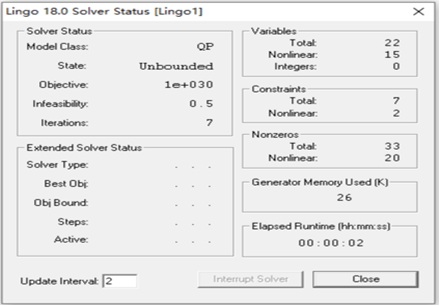

–Step 2: Solver status

After establishing the models in LINGO software, we click the software run button (target icon) to run and solve the model. The Figure 4 is the running process:

Figure 4. Solver status of the linear programming model and constraints of N types of products

– Step 3: Running results

Through the super operation of the software LINGO, we get the final result of the model in an instant, as shown in Table 2. Here, it is important to explain that the objective value and its numerical value should appear in Table 2, because the objective value is the optimal value for constructing the objective function (the optimal value is the total maximum profit that can be obtained by using limited resources). However, there is no objective value and its numerical value in Table 2 below, because letters are used instead of numbers in the linear programming model we built, so there is no objective value and its numerical value. In practice, replacing the corresponding letter with a number will bring up the objective value and its numerical value. X,Y,D,E,..,P are the optimal solution (the optimal quantity of each product produced in a combination of products) in Table 2.

The input of the whole model is simple and intuitive, the operation speed is fast, the computing power is strong, the built-in modeling language and the internal functions are provided, the large-scale optimization model is visually described with fewer statements, the collection is introduced, the model is easy to build, easy to operate, and the data exchange with EXCEL and database is convenient, so it has strong practicality.

Table 2. Running results of the linear programming model and constraints of N types of products

| 1 | Model Class: QP | 22 | P 0.5000000E+15 -0.4210289E+15 |

| 2 | 23 | B1 1.234568 0.000000 | |

| 3 | Total variables: 22 | 24 | B2 1.234568 0.000000 |

| 4 | Nonlinear variables: 15 | 25 | B3 1.234568 0.000000 |

| 5 | Integer variables: 0 | 26 | B4 1.234568 0.000000 |

| 6 | Total constraints: 7 | 27 | BN 1.234568 0.000000 |

| 7 | Nonlinear constraints: 2 | 28 | W 0.3329958E+16 0.000000 |

| 8 | Total nonzeros: 33 | 29 | XN 0.4210289E+15 0.000000 |

| 9 | Nonlinear nonzeros: 10 | 30 | YN 0.5000000E+15 0.000000 |

| 10 | 31 | DN 0.5000000E+15 0.000000 | |

| 11 | Variable Value Reduced Cost | 32 | EN 0.5000000E+15 0.000000 |

| 12 | A1 1.234568 0.000000 | 33 | PN 0.5000000E+15 0.000000 |

| 13 | X 0.4210289E+15 0.000000 | 34 | |

| 14 | A2 0.5000000E+15 0.4210289E+15 | 35 | Row Slack or Surplus Dual Price |

| 15 | Y 0.5000000E+15 -0.4210289E+15 | 36 | 1 0.1000000E+31 1.000000 |

| 16 | A3 0.5000000E+15 -0.4210289E+15 | 37 | 2 -0.5000000 0.000000 |

| 17 | D 0.5000000E+15 -0.4210289E+15 | 38 | 3 0.000000 0.000000 |

| 18 | A4 0.5000000E+15 -0.4210289E+15 | 39 | 4 0.000000 0.000000 |

| 19 | E 0.5000000E+15 -0.4210289E+15 | 40 | 5 0.000000 0.000000 |

| 20 | M 0.3410335E+15 0.000000 | 41 | 6 0.000000 0.000000 |

| 21 | AN 0.5000000E+15 -0.4210289E+15 | 42 | 7 0.000000 0.000000 |

4. Conclusion

This method uses the production possibility frontier as the theoretical basis to construct a linear programming model of multiple products. Combined with LINGO software, it can effectively and quickly calculate and select the most suitable product combination and the maximum profit value as well as the production quantity of each product in the combination.

This combined method has good profitability and the characteristics of high efficiency, simplicity, practicality and low cost, and can simplify complex problems and make them efficient. Following the principle of circular economy reduction, it not only avoids excessive waste of resources, but also makes full use of resources to the maximum extent. At the same time, it obtains the maximum profit for manufacturing enterprises.

However, the last step of this method has certain limitations. All product quantities should be integers, but decimals will appear in the calculation process, such as half a product (0.5), which is defective and unacceptable in reality. Therefore, it is necessary to re-verify which type of product should be produced according to the resources consumed by the last product in order to obtain the complete maximum profit. At the same time, we should also consider the time-sensitive value of product sales. The optimal product production combination can help the enterprise obtain the maximum profit, but it is not necessarily the best choice in terms of time-sensitive value. For example: the enterprise obtain the maximum profit to produce product combination A, which can only be sold one batch in one year.

However, product combination B does not help the enterprise to obtain the maximum profit, but enterprise can sell 2 batches of combination B in one year, and the comprehensive profit of combination B is greater than that of combination A in one year. This timeline and integrated profit monitoring can be more intelligently solved with the help of high technology. But at present, the development of the manufacturing industry is still restricted by the mature application and popularization of various high technology, but in the future, this situation will be solved more intelligently with the mature combination and popularization of artificial intelligence technology, the Internet of Things, big data and cloud computing.

In the future, our work will focus on the application of artificial intelligence and big data technology, and even the Internet of Things technology. However, since the current development and maturity of these technologies have not yet reached generalization, this will be an important challenge for future work.

REFERENCES

Aigner, D., Lovell, C. A. K. & Schmidt, P. (2023). Reprint of: Formulation and Estimation of Stochastic Frontier Production Function Models. Journal of Econometrics, 234, 15 – 24. https://doi.org/10.1016/j.jeconom.2023.01.023

Aryal, K., Maraseni, T. & Apan, A. (2023). Understanding Production Possibility Frontiers and Utility Values of Ecosystem Services in the Himalayas: An Analysis of the Supply-demand Divide. Journal of Cleaner Production, 423, 138725. https://doi.org/10.1016/j.jclepro.2023.138725

Asmild, M., Hukom, V. Nielsen, R. & Nielsen, M. (2024). Is Economies of Scale Driving the Development in Shrimp Farming from Penaeus Monodon to Litopenaeus Vannamei? The case of Indonesia. Aquaculture, 579, 740178. https://doi.org/10.1016/j.aquaculture.2023.740178

Biolcheva, P. & Sterev, N. (2024). A Model for Calculating the Indirect Added Value of AI for Business. Strategies for policy in science and education, 32(3), 9 – 17. https://doi.org/10.53656/str2024-3s-1-mod

Blachly, B., Sims, C. & Warziniack, T. (2024). Ecosystem Complementarities: Evidence from over 700 U.S. Watersheds. Ecological Economics, 219, 108147. https://doi.org/10.1016/j.ecolecon.2024.108147

Burggräf, P., Wagner, J., Koke, B. & Bamberg, M. (2020). Performance Assessment Methodology for AI-supported Decision-making in Production Management. Procedia CIRP, 93, 891 – 896. https://doi.org/10.1016/j.procir.2020.03.047

Elbasheer, M., Longo, F., Nicoletti, L., Padovano, A., Solina, V. & Vetrano, M. (2022). Applications of ML/AI for Decision-Intensive Tasks in Production Planning and Control. Procedia Computer Science, 200, 1903 – 1912. https://doi.org/10.1016/j.procs.2022.01.391

Li, C., Chen, Y., & Shang, Y. (2022). A Review of Industrial bBg Data for Decision Making in Intelligent Manufacturing. Engineering Science and Technology, an International Journal, 29, 101021. https://doi.org/10.1016/j.jestch.2021.06.001

Molhova, M. & Biolcheva, P. (2023). Strategies and Policies to Support the Development of AI Technologies in Europe. Strategies for policy in science and education, 31(3), 69 – 79. https://doi.org/10.53656/str2023-3s-5-str

Pang, S. L., Liu, H. & Hua, G. H. (2024). How Does Digital Finance Drive the Green Economic Growth? New Discoveries of Spatial Threshold Effect and Attenuation Possibility Boundary. International Review of Economics and Finance, 89, 561 – 581. https://doi.org/10.1016/j.iref.2023.07.014

Sterev, N. (2023). Pre-Incubation Toolkits for Academic Entrepreneurship Fostering: Bulgarian Case. Strategies for policy in science and education, 31(3), 90 – 103. https://doi.org/10.53656/str2023-3s-7-pre

Sterev, N., Sabeva, M., Zlateva, R. & Dimitrova, V. (2020). Business Social Network (BSN): Does the Business Escape from Reality Impossible? In M. H. Bilgin, H. Danis, E. Demir (Eds.), Eurasian Business Perspectives. Eurasian Studies in Business and Economics, Vol. 14, no. 2 (pp 129 – 144). Springer. https://doi.org/10.1007/978-3-030-52294-0_8

Trubins, R. (2023). Trade-Offs in Ecosystem Services: Clarifying Concepts and Measuring Severity within the Production Possibility Frontier Framework. Sustainability, 15(24), 16763. https://doi.org/10.3390/su152416763

Valero-Carreras, D., Aparicio, J. & Guerrero, N. M. (2021). Support Vector Frontiers: A New Approach for Estimating Production Functions through Support Vector Machines. Omega, 104, 102490. https://doi.org/10.1016/j.omega.2021.102490

Yan, Z., Wang, Y., Hu, X. & Luo, W. (2023). Assessment and Enhancement of Ecosystem Service Supply Efficiency Based on Production Possibility Frontier: A Case Study of the Loess Plateau in Northern Shaanxi. Sustainability, 15(19), 14314. https://doi.org/10.3390/su151914314

Yang, Y., Zhang, S., Xia, F., Yang, Y., Li, D., Sun, W., Wang, Y. & Xie, Y. (2022). A Comprehensive Perspective for Exploring the Trade-offs and Synergies between Carbon Sequestration and Grain Supply in China Based on the Production Possibility Frontier. Journal of Cleaner Production, 354, 131725. https://doi.org/10.1016/j.jclepro.2022.131725

Zhou, B., Bao, J., Li, J., Lu, Y., Liu, T. & Zhang, Q. (2021). A Novel Knowledge Graph-based Optimization Approach for Resource Allocation in Discrete Manufacturing Workshops. Robotics and Computer-Integrated Manufacturing, 71, 102160. https://doi.org/10.1016/j.rcim.2021.102160