Dobrin Milev

ORCID iD: 0009-0004-3671-036X

Nikola Vaptsarov Naval Academy – Varna, Bulgaria

Todor Koritarov

ORCID iD: 0000-0002-7712-8235

Nikola Vaptsarov Naval Academy – Varna, Bulgaria

https://doi.org/10.53656/igc-2024.09

Pages 112-117

Abstract. During crude oil spills the personnel involved in the Oil industry and the emergency responders may be exposed to Crude Oil Volatile Compounds (VOC) following their release from the rig or the transportation vessel and migration through the water column to the ocean surface. In order to be prepared in case of such incidents, hand-held instruments are readily available and capable of measuring VOC in isobutylene units. Currently there’s no VOC emergency levels for crude oil vapors or developed correction factor for which to extrapolate the concentration of general VOC as isobutylene to the concentration of Crude Oil Volatile Compounds in the air. Therefore these levels must be set out as a recommendation for initial health and safety decision making immediately after an oil spill incident and for time framing during oil spill response. In this regard, the article explores the factors that influence the VOC concentration in crude oil following an accidental release and the subsequent risks associated with inhaling these vapors.

Keywords: maritime transport; Crude Oil Volatile Compounds; safety; oil spills

JEL: L91, Q53, J81

- Introduction

In the event of major crude oil spill, tanker crew, emergency responders, remediation engineers and scientists in the vicinity of the incident are in contact with the surfaced crude oil. This floating oil releases a fraction of its remaining mass into the air termed “Volatile Organic Compounds”. In the process the light end hydrocarbons as benzene may be scrubbed from the oil during its transition in the water column, the remaining volatiles are mostly dispersed via volatilization and wind dispersion. It is these surfaced Crude Oil Volatile Organic Compounds that represent a hazard to the personnel attempting to control the spill in the affected area. In this case safety levels, also known as action levels should be developed and established as a readily available instrument, playing an important role in detecting the compounds (Dimitrakiev & Gilev, 2021). After all, in the contemporary world, training and the acquisition of new knowledge determine significantly the future integration and successful realization of people in society (Dimitrakieva et al., 2023; Narleva & Gancheva, 2018).

- Volatile organic compounds safety levels

The first step in establishing crude oil volatile organic compounds safety level value is to determine the toxicity of the chemical, agent or mixture against reliable response data that describe the advance of symptoms due to increased exposure. Different organizations, agencies and institutions set exposure levels but only the American Industrial Hygiene Association provides values for crude oil organic compounds (Conev & Dimitrakiev, 2023; Dimitrakieva et al., 2021). The most sensitive endpoint for exposure to light end hydrocarbon mixture as ocular irritation, identifying a lowest observable adverse effect levels at 160 ppm. The purpose of the safety levels is to identify atmosphere concentrations of a compound prior to the development of adverse effects, a recommended level of 100 ppm is suggested for duration of up to 24 hours (AIHA, 2017). Benzene concentration is impacted by the environmental and sample variables and is recognized as health hazard. Therefore it must be monitored and its levels constantly measured.

The next step is to determine and validate a method of rapid and efficient detection of the quantity of compounds with readily available instrument in an offshore environment or during an accident (Dimitrakiev & Molodchik, 2018; Sterev, 2023). The multi-gas detectors are often provided with photoionization detectors and play the role of real time evaluators of atmospheric contaminants. The sensors of these detectors record general airborne volatile compounds and require the application of a scientifically developed chemical specific or mixture correction factor to accurately determine the quantity. The revision of the scientific literature shows that there’s no correction factor for the volatile organic compounds. There’s a necessity to establish such a correction factor when utilizing photoionization detectors for comparison of results to a safety level. There’re several approaches when developing correction factor for crude oil volatile organic compounds measurements including both a literature based mathematical approach and an empirical laboratory findings (IAPH, ICS & OCIMF, 2020).

A mathematical composition analysis approach is applied utilizing the molar composition of identified components a correction factor values for individual components. Airborne chemical mixture data are obtained from a variety of oil spill incidents as published in the scientific articles, including a seafloor release with exposure measured on oil rig. Based on this data the calculated correction factor varies between 1.2 – 2.54. slightly higher than the publications for the hydrocarbon mixtures. At the same time, a Chevron provided crude oil sample, is analyzed in the laboratory of the American National Institutes of Occupational Safety and Health for application in the empirical derivation of photoionization detector correction factor. The evaluation of vapor generated from the sample is set to 1.33 correction factor.

Generally considered for exposure scenario, a correction factor of 1.3 is recommended for crude oil vapors. Application of this factor to the 100 ppm crude oil volatile organic compounds safety levels shows that such a concentration is achieved when the multi-gas detector has a reading of 77 ppm, after a calibration of the instrument with isobutylene gas.

- Exposure scenario

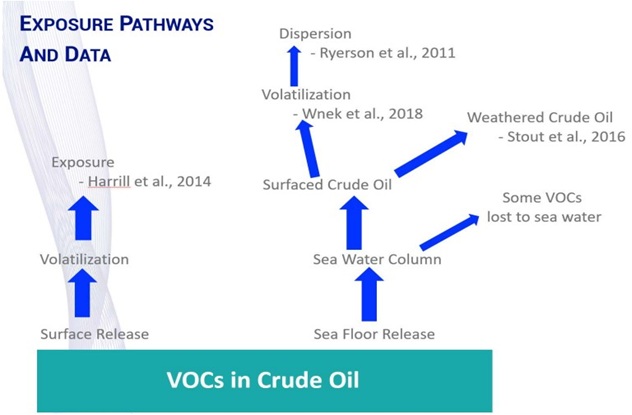

For the purpose of this scenario the crude oil is released at the seafloor, rises through the sea water column with loss of some components. After that reaches the surface and volatile organic components are released from surfacing crude oil. Volatilizing components enter the atmosphere and reach the breathing exposure zone of crew (Harill et al., 2014; Dimitrakiev et al., 2023), while other components remain in surfaced crude oil and are subject to weathering (Stout et al., 2016). Figure 1. Identifies the studies on the volatilization (Wnek et al., 2018) and dispersion (Ryerson et al., 2011). They characterize the VOC composition of vapors originating in crude oil.

Figure 1. Exposure pathway and data for crude oil volatile organic compounds

The presented exposure scenario considers a person involved in oil rig or platform industry, oil tanker shipping company, or part of oil spill response team. The worker is assumed to be present during the first 24 hours of the spill and exposed via inhalation only. The crude oil involved is released at the seabed and reaches the surface after hundred of meters. The surfaced oil is fresh, not weathered, and the VOC released will be those immediately released, or released during the initial minutes or hours of surfacing. Released crude oil continuing to surface is replenishing the VOC which may have dissipated due to wind drift or rising through the atmosphere.

In this way, the mixture of volatile organic components to which the personnel is expected to be exposed will be a subset of the component present in crude oil, reduced by concentration of pressure based off-gassing and solubilization in seawater, and low vapor pressure of some remaining components on the surface. The exposure pathway is traced in Figure 1.

- Conceptual model of volatile organic compounds impacts

Stressor: Crude oil volatile organic compounds

The model is based on the volatile constituents of source crude oil, found in some samples. The VOC content of crude oil types in the Gulf of Mexico is targeted in the model.

Source: Surfaced, non-burning crude oil

The exposure scenario includes accidental release of crude oil from seabed drilling operations. The source of the exposure is crude oil released at the sea floor and surfaced by moving upward through the water column.

Exposure media: Air

The exposure is characterized by the volatilization of crude oil volatiles in the ambient air. Thus it is assumed that individuals working on the spot may experience an inhalation exposure as part of their occupational work adjacent to surfaced oil.

Receptors: Humans (Occupational)

For the purpose of risk assessment, the target receptor is human. Furthermore, due to the job description and location, this population likely represents “healthy workers”, thus minimizing the potential for exposure to sensitive sub-populations. Humans exposed via inhalation to elevated levels of released volatile organic compounds in an acute scenario may experience symptoms of irritation and at higher levels intoxication.

Attribute change: Irritation

When exposed to crude oil volatiles can result in several types of acutely manifested as well as delayed effects, this model is focused on the initial sign of exposure and potential intoxication. Reliance on irritation as the sentinel effect will be protective against more serious effects which occur with increasing concentration.

- Conclusions

The approach to estimate a volatile organic compounds safety level incorporates a level of protectiveness and is based on an effect that is expected to be mild and reversible. This safety level is independent of gas-detection instrument reading, but the effort to develop correction factor enable rapid detection of this concentration, using basic industrial hygiene equipment, typically widely available and expected to be available during the initial phase of accidents.

The purpose of the research is to establish reliable tool as an action level for crude oil volatile organic compounds. Using the proposed action level of 100 ppm, with 1.33 applied for up to 24 hours of exposure is expected to be protective against mild, irritant effects. Based on the dose-response relationship established in the emergency planning response guidelines, this value of 100 ppm is ten-fold lower than the value established for more severe effects, which include dizziness. The photoionization detectors correction factor of 1.3 recommended for crude oil vapors can be used in rapid-reading instrumentation to effectively quantify the action level concentration.

REFERENCES

AIHA. (2017). Emergency Response Planning Guidelines and Workplace Environmental Exposure Levels. American Industrial Hygiene Association.

Conev, I. & Dimitrakiev, D. (2023). Use of Modern Technologies at Naval Academy Varna. Proceedings of the International Association of Maritime Universities (IAMU) Conference, 129 – 135.

Dimitrakiev, D. & Gilev, G. (2021). Green Ports – Environmental Challenges and Economic Demands. Pedagogika-Pedagogy, 93(7s), 132 – 140. https://doi.org/10.53656/ped21-7s.11gree

Dimitrakiev, D. & Molodchik, A. (2018). Digital Platforms as Factor Transforming Management Models in Businesses and Industries. Journal of Physics: Conference Series, 1015, 042040. https://doi.org/10.1088/1742-6596/1015/4/04204

Dimitrakiev, D., Stankov, V. & Atanasova, C. (2023). Simulator Training – Unique Powerful Instrument for Educating, Skills Creating, Mitigating Skills and Resilience Creating. Strategies for Policy in Science and Education, 31(6s), 103 – 111. https://doi.org/10.53656/str2023-6s-9-sim

Dimitrakieva, S., Kostadiniv, O. & Atanasova, K. (2023). Pools in Tramp Shipping and the Rules on Competition Given the Art. 101 of the Treaty on the Functioning of the European Union. Strategies for Policy in Science and Education, 31(3s), 140 – 147. https://doi.org/10.53656/str2023-3s-11-poo

Dimitrakieva, S., Kostadinov, O. & Atanasova, K. (2021). Multilevel Demand for Sea Transportation: Correlation between Baltic Dry Index (BDI) and Coaster Shipping Prices for Sea Routes between Baltic Seaports and Mediterranean Seaports. Pedagogika-Pedagogy, 93(7s), 141 – 148. https://doi.org/10.53656/ped21-7s.12corr

Harill, J. A., Wnek, S. M., Pandey, R. B., Cawthon, D., Nony, P. & Goad, P. T. (2014). Strategies for Assessing Human Health Impacts of Crude Oil Releases. International Oil Spill Conference Proceedings, 2014(1), 1668-1685. https://doi.org/10.7901/2169-3358-2014.1.1668

IAPH, ICS & OCIMF. (2020). International Safety Guide for Oil Tankers and Terminals (ISGOTT 6). (6th Ed.).

Narleva, K. & Gancheva, Y. (2023). The Role of Maritime Education in Digitalization. Pedagogika-Pedagogy, 95(6s), 132 – 141. https://doi.org/10.53656/ped2023-6s.12

Ryerson, T. B., Aikin, K. C., Angevine, W. M., Atlas, E. L., Blake, D. R., Brock, C. A., Fehsenfeld, F. C., Gao, R.-S., Gouw, J. A., … & Watts, L. A. (2011). Atmospheric Emissions from the Deepwater Horizon Spill Constrain Air-water Portioning, Hydrocarbon Fate and Leak Rate. Geophysical Research Letters, 38(7), L07803. https://doi.org/10.1029/2011GL046726

Sterev, N., (2023). Pre-Incubation Toolkits for Academic Entrepreneurship Fostering: Bulgarian Case. Strategies for Policy in Science and Education, 31(3s), 90 – 103. https://doi.org/10.53656/str2023-3s

Stout, S. A., Payne, J. R., Emsbo-Mattingly, S. D. & Baker, G. (2016). Weathering of Field-Collected Floating and Stranded Macondo Oils During and Shortly after the Deepwater Horizon Oil Spill. Marine Pollution Bulletin, 105(1), 7 – 22. https://doi.org/10.1016/j.marpolbul.2016.02.044

Wnek, S. M., Kuhlman, C. L., Harrill, J. A., Nony, P. A., Millner, G. C. & Kind, J. A. (2018). Forensic Aspects of Airborne Constituents Following Releases of Crude Oil into the Environment. In S. A. Stout, Z. Wang (Eds.), Oil Spill Environmental Forensics Case Studies (pp. 87 – 115). Elsevier. https://doi.org/10.1016/B978-0-12-804434-6.00005-7