Ivanka Peeva

University of Ruse “Angel Kanchev”, Ruse, Bulgaria

Chavdar Kostadinov

Rakovski National Defence College, Sofia, Bulgaria

https://doi.org/10.53656/adpe-2025.07

Pages 74-82

Abstract. Analytical and simulation modeling are commonly used methods for analysis and optimization of manufacturing systems in various industrial fields. In the presented paper, some considerations relevant to the creation of models used in the design of new or operation of existing robotic process modules constituting manufacturing systems are discussed.

Keywords: modeling; model; production system; robotic technological module; industrial robot

- Introduction

The construction and operation of automated production systems in practice is associated with the analysis and selection of suitable objects for automation, consideration of possible technical options for the composition of technical equipment implementing a necessary technological process under specific production conditions. In engineering practice, various methods are used for modeling of production systems and processes, in order to find the optimal variant of implementation, providing the selected values of performance criteria. In the analytical determination of the technical performance, along with the cycle time, characteristic own off-cycle losses, some of which are random in nature, are taken into account. The interaction between the different components of the production system and the impact on the overall performance can be analyzed by probabilistic modelling. The use of Queueing Theory (QT) for the purpose of engineering practice is based on the analysis of the performance and possible states of manufacturing systems where the arrival and service times of requests are considered as random quantities.

- Features of modelling production systems

A major trend in modern industrial production is the increasing share of batch production, determined by increasing competition and new market conditions. This necessitates the construction of flexible automated production systems, having the possibility of rapid reconfiguration and wide use.

Robotic technological modules (RTM), made up of one or several programmable process machines operated by a single industrial robot (IR), are commonly used production systems operating both stand-alone and as part of process complexes and other production structures.

This makes the issues of modelling their operation and investigating key features particularly important to ensure efficient operation under certain manufacturing conditions. Compilation and application of an appropriate mathematical model based on QT and linking the set and investigated parameters of the production system requires a thorough knowledge of the real system and the processes taking place in it.

When organizing the work of the production system, to achieve the effective use of equipment implementing a certain production technology, various technological and design options are sought to ensure appropriate service times (Kostadinov, 2017).

This is associated with solving the problems of optimization of the service trajectory, determining appropriate speeds for movement along the individual degrees of mobility of the robot, etc.

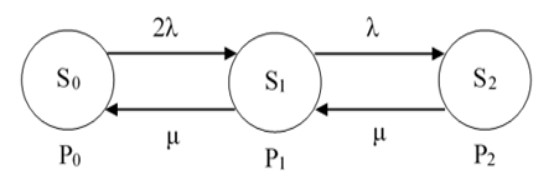

The type and characteristics of the auxiliary equipment, as well as the general layout of the module are important. The effective use of the different types of equipment in the composition of the technological module depends on the ratios Ρ ( = 1÷m) of the processing and servicing times of m per number of machines implementing the production process (Penchev, 1997). The most widely used PTMs have one or two process machines operated by one robot, but systems with more machines exist. If machines M1 and M2 of a robotic module have the same or similar process capabilities, or for modelling purposes it is possible to consider them so, then the running times are assumed to be equal (tM1 ≈ tM2). According to the QT, the use of a linear graph type Fig. 1 (Kostadinov, 2017) is appropriate to represent the possible states of the system.

Figure 1. Line graph of the states of a robotic module of 2 machines; λ, request intensity; µ, service intensity; si – system state; pi – state probability; i – number of idle machines

The analytical model of the considered module is represented by the system of equations for each of the states:

![]()

(1)

![]()

(2)

![]()

(3)

With λ/μ = ρ and solving the system of equations (1-3), the final state probabilities P are obtained:

![]()

(4)

The loads of the NM machines and the HP robot are:

![]()

(5)

![]()

(6)

The expected performance of the module depends on the work organization. In parallel operation of the machines, the system throughput is P = 2λHM, and in sequential operation P = λHM (taking into account the respective intensities).

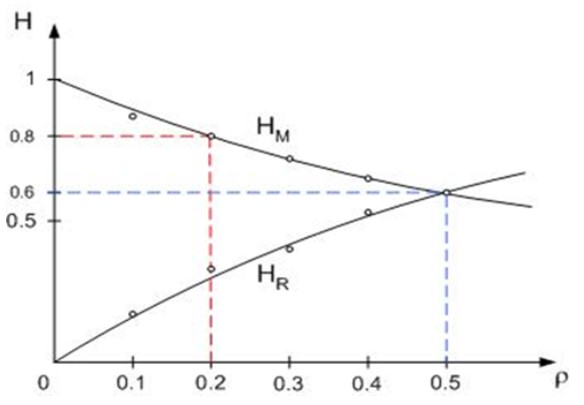

Using equations (5) and (6) and with different allowable values of ρ, the variation of the corresponding loads can be predicted. Fig. 2 (Penchev, 1997) shows graphically the variation of the main and auxiliary equipment loads over the allowable range of variation of the relative intensity ρ for a fixed number of machines m = 2 (0 < ρ < 0.5). For larger values of ρ the service time exceeds the machining time, which is not appropriate in real conditions and is not considered. A set minimum value for the machine load HM = 0.8, corresponding to the requirements in automated production, determines the maximum value of ρ. The minimum permissible values of the equipment loads define the size of the possible region [ρ]min ÷ [ρ]max in which such a ρ exists providing an efficient technical solution (Penchev, 1997). The graph shows that for high machine and robot load requirements there may be no such solution.

Figure 2. Load on the HM machines and on the HR robot at RTM and m = 2

Determination of the allowable area for relative intensity variation can be used to target the selection of layout, main and auxiliary equipment in the design of a RTM, as well as to determine process modes that ensure efficient operation of a real system under certain operating conditions (Penchev, 1997). If the machine tools in the module have different technological capabilities (tM1 ≠ tM2), then a branching graph is appropriate to describe the system operation, where the possible states with consideration of service waiting losses (for reliable equipment) are S ( = 0 ÷ 5). If the running and handling times are different, it is necessary to account for which machine is running, which is being serviced, and which is waiting for service at a busy IP. The final state probabilities are obtained after solving a system of 5 equations describing the states in the model (Kostadinov, 2017). The resulting values can be used to predict throughput, service waiting losses and other characteristics of the RTM.

The efficient operation of the system depends on the chosen scenario for servicing the machines. In sequential operation RTM, the performance is set by the machine with the higher machine time. The service waiting losses are determined by the time to manipulate the IP at a given trajectory and travel speed, the type of gripper used (single or double), and the sequence of the machine being serviced. The scenario is also essential in systems with parallel operation (Kostadinov, 2017). The need to consider such factors is related to distinguishing additional states, which makes it difficult to create and solve an analytical model. Finding appropriate solutions is possible by means of simulation modelling.

- Robotic machining process module

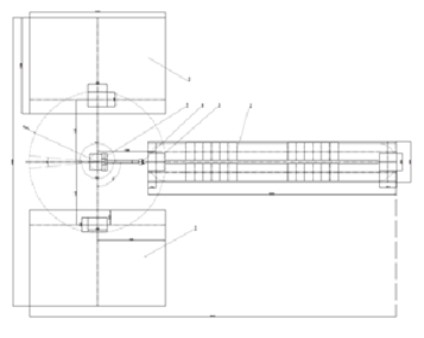

A machine-building company realizing serial production has CNC machine tools for machining rotationally symmetrical parts. The technological processes for machining a group of „Flange“ type workpieces include turning operations, which in general have different operating times under accepted operating modes. Taking into account the wide range for modification of technical parameters of turning machines, allowing machining of a range of workpieces, the possibility of developing RTM for turning machining is considered. If in the general case the technological process requires turning and stopping of a semi-finished workpiece, two basic structural variants of the RTM are possible – with one or two technological machines. Considering the working conditions in batch production, the required flexibility and the emerging need for machining different rotationally symmetrical workpieces in the company, it is appropriate to use a RTM for turning made up of two machines and one IR. Fig. 3 shows a module including two turning machines (pos. 5) T-350 RAIS (Bulgaria), 1 – IR – KR 16 R1610-2 (KUKA) and 2- feed-unloader Versamove (MK Technology Group).

When the machines are operated in sequence, the workpieces are fed from the feeder to the two machines in turn for the respective machining, with the IP leaving the finished workpiece on the same fixture. The running time of the first machine is tM1 = 19.46 min, tM2 = 8.83 min.

In accordance with the presented layout, taking into account the dimensions of the units, the required movements of the IP by the different degrees of mobility are analytically determined. With the symmetrical arrangement of the machines relative to the IPs and the data on the travel speeds of the individual degrees of mobility, a service time tobsl = 24.4 s (tobslM1 = tobslM2 = tobsl) was obtained. Parallel operation is also possible. The two machines perform operations 1 and 2 independently with intermediate turning of the semi-finished workpiece by the IP of each machine. The productivity of the PTM will be the sum of the productivity of the two machines.

Figure 3. RTM for mechanical processing

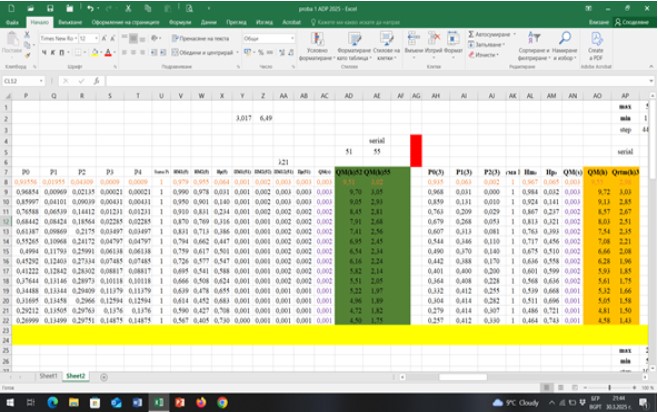

To predict the performance of the considered module under sequential operation of the machines, two analytical models were used, under linear and branching state graph, and the results were obtained based on the derived dependencies (Kostadinov, 2017) in Excel environment (Fig. 4).

Figure 4. Determination of performance in analytical modelling

As the service time, represented by the variation of ρ, increases, the performance of the RTM decreases, and the significant differences in the two analytical models are due to averaging the machine times over a linear graph. For large differences of times and consistent processing, it is appropriate to use an analytical model with a branching state graph accounting for the service waiting losses for each machine, which affects the final throughput. Changing the servicing time in the described setup can be realized by optimizing the servicing cycle, by motion reconciliation, or by selecting an appropriate, technically feasible robot motion speed along the different degrees of mobility. As the difference between the machine times increases, the difference in the predicted performance values of the two models increases. In the case under consideration, the linear graph model does not take into account the order of service of the machines.

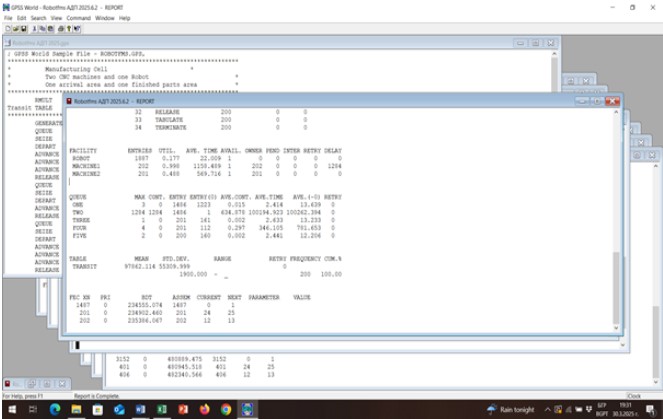

A type simulation model in the (GPSS, 2001) environment (Schreiber, 1980) was used to benchmark the performance of the presented RTM.

Multiple simulations were performed at a given number of processing cycles. Fig. 5 shows the GPSS generated report, where for 200 cycles performed, the average values of the loads were obtained as HM1 = 0.99; HM2 = 0.488 and HR = 0.177. The exponential law of distribution of random variables was set. Given the convergence of the results with those obtained from analytical modelling, it can be assumed that the simulation model is reliable and can be used.

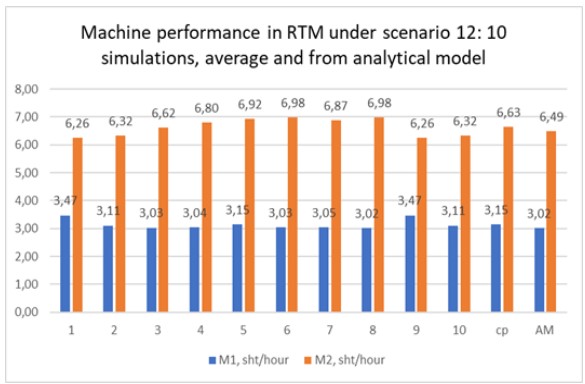

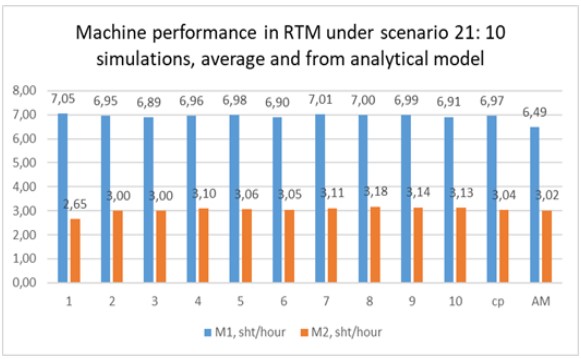

Fig. 6 and Fig. 7 graphically show the performance results of the two machines from 10 runs of simulations with 100 cycles of sequential machining and different sequences of machine servicing (GPSS, 2001). The average performances of the two machines in the two scenarios are different and larger than those obtained using the analytical model with a branching graph. The comparison shows that, even with identical service times, considering the probabilistic nature of the arrival of requests in the system, given an appropriate law for the distribution of random variables, can increase the accuracy of the simulation results. With other layout decisions or factors determining different service times for the two machines in the module, more significant performance differences can be expected when changing the service scenario (Norenkov, 2009).

Figure 5. Simulation modelling of RTM

Figure 6. Performance of machines in the RTM under a scenario with service sequence (M1 – M2), mean (cp) and performance from analytical model (AM)

In real operating conditions, by setting values for minimum allowable machine and robot loads, the intensity variation range ρmin < ρ < ρmax can be determined to obtain machine processing times that provide the system performance criteria. In this way, it is possible to determine the objects for the automated production of which, with appropriate technology and work organization, it is appropriate to use the equipment under consideration.

The structured RTM can be used for machining of various rotary workpieces in batch production conditions and function as:

- A single-machine RTM and a service IP;

- A RTM of two machines and an IR working in series;

- A RTM of two machines running in parallel and an IR.

Figure 7. Performance of machines in the RTM under scenario (M2 – M1), mean (cp) and performance from analytical model (AM)

The programmable machines and the selected IR allow the equipment to be reconfigured for different workpieces. The efficient operation of the module is determined by the ratio of processing and service times ρ < 0.5. For larger values of ρ the service time exceeds the machining time, which is not appropriate in real conditions and is not considered.

- Conclusions and summaries

The optimization of technological processes for automated production is a major issue in the development and operation of RTMs, due to the multivariate nature of the possible solutions defined by the wide range of technical parameters of the main CNC technological equipment and industrial robots. For this purpose, it is appropriate to use analytical or simulation modelling of the system performance under certain operating conditions. Taking into account the probabilistic nature of the requests and services entering the system and using an appropriate simulation model leads to more accurate performance predictions, which would support the efficient operation of the production system.

Acknowledgements

This study is financed by the European Union-NextGenerationEU, through the National Recovery and Resilience Plan of the Republic of Bulgaria, project № BG-RRP-2.013-0001.

GPSS world reference manual. (2001). Holly Springs. https://athena.ecs.csus.edu/~mitchell/csc148/gpssW/Reference%20Manual/rpreface.htm

Kostadinov, C. (2017). Probabilistic modeling, analysis and performance forecasting of production systems with a parallel structure [Doctoral thesis]. University of Ruse “Angel Kanchev”.

Norenkov, I. P. (2009). Basis of Computer-aided design: Educational supplies for universities. (4th ed.). Bauman MSTU.

Penchev, M. (1997). Performance criteria for robotic modules in analysis and design tasks. Scientific Proceedings of NTS of Mechanical Engineering, 4(8), 190 – 195. [in Bulgarian]

Schreiber, T., (1980). GPSS modeling. Mechanical Engineering.

Assoc. Prof. Ivanka Peeva, PhD

ORCID iD: 0000-0002-5725-6889

University of Ruse “Angel Kanchev”

Ruse, Bulgaria

E-mail: ipeeva@uni-ruse.bg

Assoc. Prof. Chavdar Kostadinov, PhD

ORCID iD: 0000-0001-5358-7122

Rakovski National Defence College

Sofia, Bulgaria

E-mail: ch.kostadinov@rndc.bg