Stiliyan Nikolov

ORCID iD: 0000-0002-2485-3847

Web of Science Researcher ID: ACY-7901-2022

Technical University of Sofia, Bulgaria

Reneta Dimitrova

ORCID iD: 0000-0001-6594-131X

Web of Science Researcher ID: GWZ-2447-2022

Technical University of Sofia, Bulgaria

https://doi.org/10.53656/adpe-2025.19

Pages 217-228

Abstract. The article discusses the optimization of the mass of an orientation module for a delta robot. The stages of the process of optimizing the mass of designed products are defined, taking into account the specifics of their design. Recommendations for using the defined stages are given. Topological optimization of details of the orientation module design, determined according to the given criteria at the relevant stage of the optimization process, was performed. The defined stages are applied to the optimization of the orientation module for a delta robot.

Keywords: topological optimization; orientation module; CAE system; product design

- Introduction

Part of the design process of products is optimizing their mass. Modern CAE systems have specialized tools for solving this task. These are tools for topology optimization, which can be considered as a form of structural optimization, solving one of the most common engineering problems – how to create a sufficiently strong part using the least amount of material.

Topology optimization methods are most often based on the finite element method (FEM), which is a powerful numerical method widely used to solve engineering problems (Bici et al., 2017). The essence of topology optimization consists in using FEA-based simulations to assess which areas of a given part are not structurally critical (Bodog & Grebenişan, 2022). These are areas in which the stresses generated during the operation of the part are less than those allowed for the material from which it is made. The results obtained are used by the algorithm built into the system to determine which areas of the part can be removed.

The algorithm continuously evaluates the stress distribution while removing material to assess the resulting effects. This is done in many separate steps until a stable shape of the part is obtained, taking into account the specified loads and boundary conditions (Malakov & Zaharinov, 2021). Topological optimization is used in many industrial sectors where weight reduction is essential (Zach & Dudescu, 2021; Mitev & Malakov, 2024; Tomov, 2017). In this article, topology optimization will be used to reduce the weight of a module for orientation for a delta robot. Robots with parallel kinematics find an extremely wide range of applications.

They allow the weight of the manipulated object to be distributed between several kinematic chains, which provides higher load capacity and better dynamic parameters compared to robots with sequential kinematics of the same size (Dichev et al., 2024; Mitev, 2024).

One of the most suitable for use are delta robots, which implement 3 degrees of freedom, ensuring the positioning of the manipulated object at any point of the robot’s workspace. Adding an orientation module to the movable platform of the delta robot provides additional degrees of freedom, through which the manipulated object can some the necessary poses (Dichev et al., 2021; Vassilev & Komarski, 2024). This design of a delta robot with an added orientation module combines the advantages of industrial robots with sequential and parallel kinematics.

- Task statement

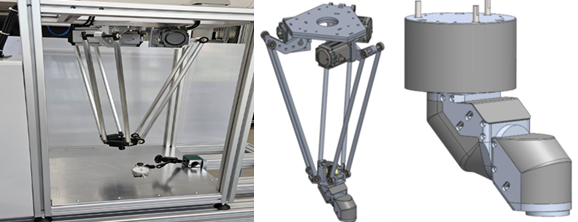

The delta robot for which the orientation module was designed, its 3D model with the orientation module, and a 3D model of the orientation module are shown in Fig. 1.

Figure 1. Delta robot with orientation module

The use of such an orientation module can significantly increase the possible applications of the delta robot. The module allows for reorientation of the manipulated objects.

The payload of the delta robot is 5 [kg]. The mass of the developed orientation module is 3.6 [kg]. This means that the maximum mass of the objects manipulated by the robot using the developed module is 1.4 [kg].

The goal is to optimize the design of the orientation module so that the robot can manipulate objects with a mass of 1.5 [kg].

- Topological optimization of products mass

Regardless of the product design, the following main stages of the process of optimizing its mass can be defined:

3.1. Stage One – Analysis of design

At this stage, the parts and assemblies included in the design of the product are divided into the following groups:

- Group 1 Standardized not allowing mass reduction – these are parts and assemblies purchased from external suppliers and incorporated into the design of the product, the mass of which cannot be reduced (engines, bearings, hydro and pneumatic cylinders, fasteners, etc.);

- Group 2 Standardized allowing for mass reduction – these are parts purchased from external suppliers and incorporated into the design of the product, the mass of which can be reduced (pulleys, gears, structural profiles, etc.) without affecting their functionality;

- Group 3 Unique not allowing for mass reduction – these are parts and assemblies designed specifically for the product, whose mass is determined as a result of their strength calculation and cannot be changed without affecting their functionality;

- Group 4 Unique allowing for mass reduction – these are parts designed specifically for the product, whose mass is determined based on the functions they perform and can be varied within certain limits.

3.2. Stage Two – Selecting parts for optimization

After dividing the parts into groups, the basic mass of the product is determined, which is not subject to reduction (the sum of the masses of parts and assemblies from groups 1 and 3). This mass can be used as a criterion for assessing the feasibility of carrying out the remaining stages. If this mass is too large, over 85% of the total mass of the product, it should be assessed whether reducing the mass of the parts from the remaining groups can achieve the desired goal.

The parts from groups 2 and 4 are arranged in descending order of their mass, in order to determine those whose mass reduction will have the desired effect of the optimization. Reducing the mass of parts whose percentage share in the total mass of the product is less than 1% will in most cases not have a significant impact on the final result.

Based on the results obtained at this stage, the parts whose mass optimization will lead to the desired result are determined.

3.3. Stage Three – Optimizing the mass of the determined parts

For some of the parts in this group, mass reduction can be achieved by drilling holes that do not violate their functional characteristics (pulleys, gears, etc.).

For the rest, it is necessary to conduct topological optimization in the following steps:

- development of a computational model that takes into account the loads and constraints acting on the part;

- determination of the strength characteristics of the part;

- performance of topological optimization under the specified loads and constraints;

- creation of a new part taking into account the results of the optimization;

- strength check of the new part;

- evaluation of the optimization result.

3.4. Stage four – Evaluation of results from the performed optimization of the product mass

At this stage, the total weight reduction of the product is determined, the achieved weight reduction is evaluated and a decision is made on the appropriateness of its implementation.

Since weight reduction using traditional processing technologies is associated with additional costs, it must be assessed whether the achieved weight reduction of the product is worth these costs.

- Optimizing the mass of an orientation module for delta robots

The defined stages for optimizing the mass of products will be used in optimizing the mass of the orientation module shown in Fig. 1.

4.1. Stage One – Analysis of design

The orientation module has sequential kinematics, 3 rotational joints, providing 3 degrees of freedom (DOF), allowing the manipulated objects to assume the necessary poses. It is made up of 144 parts and assemblies, which, according to the considerations made in part 3 of the article, fall into the groups given in tables 1 to 4:

Table 1. Group 1 Standardized parts not allowing mass reduction

| № | Name | Pieces | Mass [g] | Total mass [g] |

| 1 | Stepper Motor Nema 17 | 3 | 600.00 | 1800.00 |

| 2 | Bearing B6810ZZ | 1 | 71.53 | 71.,53 |

| 3 | Bearing B6807 | 1 | 37.10 | 37.10 |

| 4 | Bearing B6805ZZ | 1 | 32.29 | 32.29 |

| 5 | Bearing JFM-3034-20 | 1 | 4.96 | 4.96 |

| 6 | Bearing JFM-2023-21 | 1 | 2.61 | 2.61 |

| 7 | Bearing JTM-2036-15 | 3 | 1.04 | 3.12 |

| 8 | Timing Belt GBN2493GT-60×255 | 2 | 11.2 | 22.4 |

| 9 | Timing Belt GBN2043GT-60×210 | 3 | 9.5 | 28.5 |

| 10 | Timing Belt GBN1893GT-60х195 | 1 | 7.6 | 7.6 |

| 11 | Support RollerH1RLM-0511-30 | 4 | 5.22 | 20.88 |

| 12 | Support Roller H1RLM-0511-24.5 | 2 | 5.21 | 10.42 |

| 13 | Support Roller H1RLM-0511-20 | 3 | 2.07 | 6.21 |

| 14 | Axle for Support Roller SFJW5-49-M3-N3 | 1 | 6.68 | 6.68 |

| 15 | Axle for Support Roller SFJW5-60-M3-N3 | 2 | 2.85 | 5.70 |

| 16 | Axle for Support Roller SFJW5-20-M3-N3 | 3 | 2.34 | 7.02 |

| 17 | Socket Head Cap Screw М 2,5х4 | 8 | 0.44 | 3.52 |

| 18 | Socket Head Cap Screw М 2,5х6 | 19 | 0.52 | 9.88 |

| 19 | Socket Head Cap Screw М 2,5х10 | 32 | 0.67 | 21.44 |

| 20 | Slotted Set Screw М 3х10 | 8 | 0.48 | 3.84 |

| Total Pieces | 99 | |||

| Total mass | 2105.70 | |||

Table 2. Group 2 Standardized allowing for mass reduction

| № | Name | Pieces | Mass [g] | Total mass [g] |

| 1 | Timing Pulley GPA48GT3060-A-H30 | 4 | 23.78 | 95.12 |

| 2 | Timing Pulley GPA48GT3060-A-H20 | 4 | 15.78 | 63.12 |

| 3 | Timing Pulley GPA22GT3060-A-P6 | 3 | 7.6 | 22.8 |

| Total Pieces | 11 | |||

| Total mass | 181.04 | |||

Table 3. Group 3 Unique not allowing for mass reduction

| № | Name | Pieces | Mass [g] | Total mass [g] |

| 1 | Shaft – 1 | 1 | 62.86 | 62.86 |

| 2 | Shaft – 2 | 1 | 62.14 | 62.14 |

| 3 | Shaft – 3 | 1 | 55.97 | 55.97 |

| 4 | Shaft – 4 | 1 | 31.95 | 31.95 |

| 5 | Shaft – 5 | 1 | 24.24 | 24.24 |

| 6 | Shaft – 6 | 1 | 16.43 | 16.43 |

| 7 | Shaft – 7 | 3 | 8.50 | 25.5 |

| 8 | Flange – 1 | 1 | 19.78 | 19.78 |

| 9 | Flange – 2 | 1 | 18.96 | 18.96 |

| 10 | Flange – 3 | 1 | 16.17 | 16.17 |

| 11 | Flange – 4 | 1 | 11.08 | 11.08 |

| 12 | Body – 1 | 1 | 192.88 | 192,88 |

| 13 | Body – 2 | 1 | 56,33 | 56.33 |

| 14 | Body – 3 | 1 | 48.49 | 48.49 |

| 15 | Body – 4 | 1 | 44.09 | 44.09 |

| 16 | Body – 5 | 1 | 35.05 | 35.05 |

| 17 | Support – 1 | 1 | 50.07 | 50.07 |

| 18 | Support – 2 | 1 | 40.87 | 40.87 |

| 19 | Support – 3 | 1 | 30.35 | 30.35 |

| 20 | Column | 3 | 37.24 | 111.72 |

| 21 | Cover – 1 | 1 | 36.87 | 36.87 |

| 22 | Cover – 2 | 1 | 17.62 | 17.62 |

| 23 | Cover – 3 | 1 | 13.97 | 13.97 |

| 24 | Cover – 4 | 1 | 4.06 | 4.06 |

| 25 | Cover – 5 | 1 | 3.84 | 3.84 |

| Total Pieces | 29 | |||

| Total mass | 939.81 | |||

Table 4. Group 4 Unique allowing for mass reduction

| № | Name | Pieces | Mass [g] | Total mass [g] |

| 1 | Base | 1 | 209.43 | 209.43 |

| 2 | Plate – 1 | 2 | 42.87 | 85.74 |

| 3 | Plate – 2 | 2 | 38.81 | 77.62 |

| Total Pieces | 5 | |||

| Total mass | 372.79 | |||

4.2. Stage Two – Selecting parts for optimization

Based on the data in tables I to IV, the total mass of the orientation module is 3599.34 [g]. Its base mass, which is not subject to reduction, is 3045.51 [g] – 84.6% of the total mass.

The mass of the orientation module parts from groups 2 and 4 is 553.83 [g]. The need to reduce the mass of the orientation module by 100.00 [g] means reducing the mass of the parts from groups 2 and 4 by 18.1% or 2.8% of the total mass of the orientation module.

To achieve the set goal, based on the above data for mass optimization, the following parts were selected: Base; Plate – 1; Plate – 2; Timing Pulley GPA48GT3060-A-H30 and Timing Pulley GPA48GT3060-A-H20.

4.3. Stage Three – Optimizing the mass of the determined parts

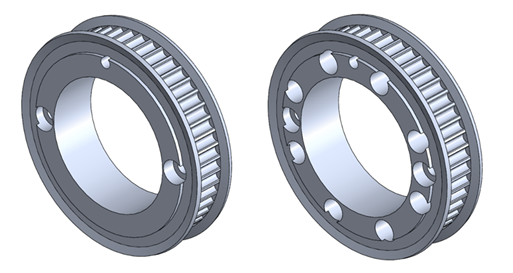

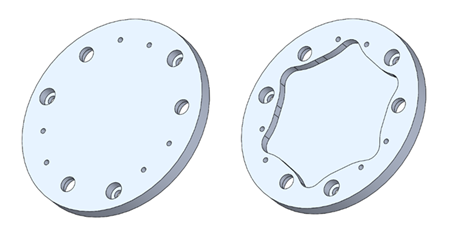

- Optimizing the mass of standardized parts allowing mass reduction

Considering the function and design of the parts in this group, reducing their mass is most appropriate to be done by drilling holes parallel to their axis of rotation, which does not violate their strength characteristics. The results obtained are shown in Fig. 2 and Fig. 3.

a/ before optimization b/ after optimization

Figure 2. Optimization of the mass of a part Timing Pulley GPA48GT3060-A-H30

a/ before optimization b/ after optimization

Figure 3. Optimization of the mass of a part Timing Pulley GPA48GT3060-A-H20

The mass of the part, Timing Pulley GPA48GT3060-A-H30, before optimization is 23.78 [g]. The mass of the part after optimization is 19.15 [g]. The achieved mass reduction is 4.63 [g] or a total of 18.52 [g] for the orientation model.

The mass of the part, Timing Pulley GPA48GT3060-A-H20, before optimization is 15.79 [g]. The mass of the part after optimization is 12.10 [g]. The achieved mass reduction is 3.69 [g] or a total of 14.76 [g] for the orientation model.

- Optimizing the mass of unique parts allowing mass reduction

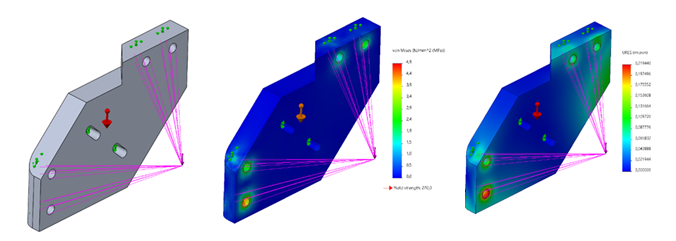

To optimize the mass of unique parts, it is necessary to conduct topological optimization.

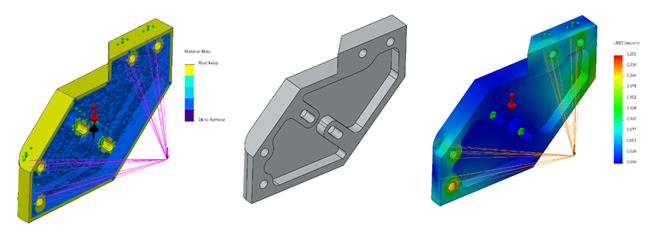

The individual steps of the performed topological optimization and its results for detail Plate – 1 are:

- development of a computational model – taking into account the forces acting on the part during operation caused by its own weight 0.4 [N], the weight of the remaining parts and assemblies 23.5 [N] and the weight of the manipulated objects 14.7 [N] Fig. 4.a;

- determination of the strength characteristics of the part – maximum von Mises stresses obtained 4.9 [MPa], maximum displacements obtained 0.22 [μm] Fig. 4.b;

- topological optimization under the specified loads and constraints, in order to obtain a minimum mass with permissible maximum displacements in the part 5[μm] Fig.5.a;

- creation of a new part taking into account the results of the optimization Fig.5.b;

- strength testing of the new part maximum stresses obtained by von Mises 5.1[MPa], maximum displacements obtained 0.25 [μm] Fig.5.c

a) computational model b) strength characteristics

Figure 4. Optimization of the mass of a part Plate – 1

a) topological optimization b) optimized part c) strength characteristics

Figure 5. Result of optimizing the mass of a part Plate – 1

As a result of the optimization carried out, the mass of the detail Plate – 1 was reduced by 13.59 [g], from 42.87 [g] to 29.28 [g], or in total for the orienting model, the mass was reduced by 27.18 [g].

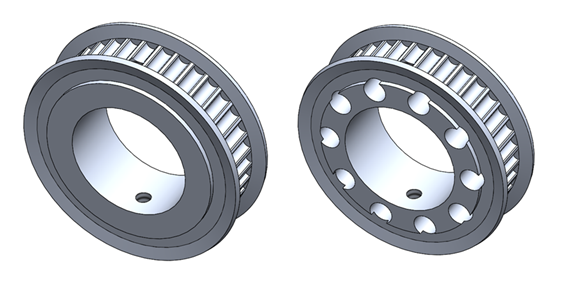

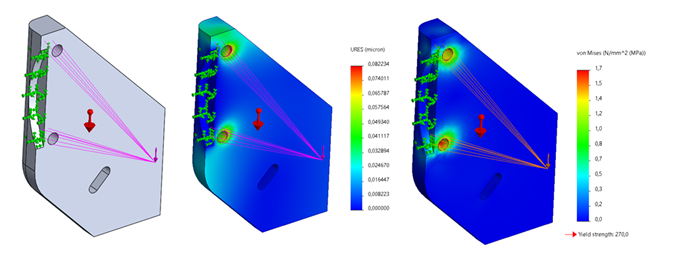

The individual steps of the performed topological optimization and its results for detail Plate – 2 are:

- development of a computational model – taking into account the forces acting on the part during operation caused by its own weight 0.38 [N], the weight of the remaining parts and assemblies 10.5 [N] and the weight of the manipulated objects 14.7 [N] Fig.6.a;

- determination of the strength characteristics of the part – maximum von Mises stresses obtained 1.7 [MPa], maximum displacements obtained 0.08 [μm] Fig.6.b;

- topological optimization under the specified loads and constraints, in order to obtain a minimum mass with permissible maximum displacements in the part 5[μm] Fig. 7 a;

a) computational model b) strength characteristics

Figure 6. Optimization of the mass of a part Plate – 2

a) topological optimization b) optimized part c) strength characteristics

Figure 7. Result of optimizing the mass of a part Plate – 2

- creation of a new part taking into account the results of the optimization Fig. 7.b;

- strength testing of the new part maximum stresses obtained by von Mises 0.1[MPa], maximum displacements obtained 0.01 [μm] Fig. 7.c.

As a result of the optimization carried out, the mass of the part Plate – 2 was reduced by 12.3 [g], from 38.81 [g] to 26.51 [g], or in total for the orienting model, the mass was reduced by 24.6 [g].

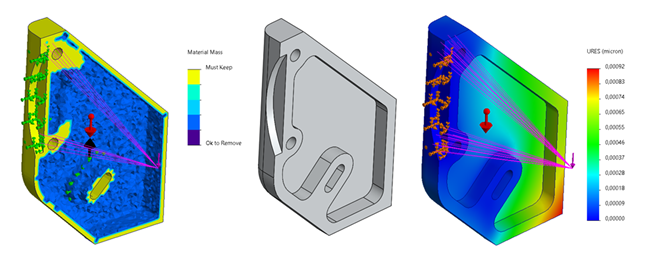

The result of the optimization of the mass of the part Base is shown in Fig. 8. The mass of the part is reduced by 67.84 [g], from 209.43 [g] to 141.59 [g].

a) before optimization b) after optimization

Figure 8. Optimization of the mass of a part Base

4.4. Stage four – Evaluation of results from the performed optimization of the product mass

The results of the optimization performed are given in Table 5.

Table 5. Results of the optimization performed

| № | Name | Pieces | Mass [g]

before |

Mass [g]

after |

Total mass reduction [g] |

| 1 | Timing Pulley GPA48GT3060-A-H30 | 4 | 23.78 | 19.15 | 18.52 |

| 2 | Timing Pulley GPA48GT3060-A-H20 | 4 | 15.78 | 12.10 | 14.76 |

| 3 | Base | 1 | 209.43 | 141.59 | 67.84 |

| 4 | Plate – 1 | 2 | 42.87 | 29.28 | 27.18 |

| 5 | Plate – 2 | 2 | 38.81 | 26.51 | 24.6 |

| Total mass reduction for the entire module | 152.93 | ||||

The data in Table V show that the set optimization goal – reducing the total mass of the orientation module by 150 [g] – has been achieved.

- Conclusions

The stages of the process of optimizing the mass of designed products are defined, taking into account the specifics of their construction. The defined stages are applied to the optimization of the orientation module for a delta robot. As a result of the optimization of the orientation module for a delta robot, its total mass is reduced by 150 [g], and the mass of the parts that the robot can manipulate is increased to 1.5 [kg]. The defined stages of the process of optimizing the mass of designed products are universal and can be used in the design of various products.

Acknowledgement

This research was funded by the Research and Development Sector at the Technical University of Sofia. The authors thank the Research and Development Sector at the Technical University of Sofia for their financial support.

REFERENCES

Bici, M., Broggiato, G., Campana, F. (2017). Topological optimization in concept design: starting approach and a validation case study. In B. Eynard, V. Nigrelli, S., Oliveri, G. Peris-Fajarnes, S. Rizzuti (Eds.). Advances on Mechanics, Design Engineering and Manufacturing. Lecture Notes in Mechanical Engineering (pp. 289 – 299). Springer. https://doi.org/10.1007/978-3-319-45781-9_30.

Bodog, A., Grebenişan, G. (2022). An integrated approach of topological optimization with parametric validation and response surfaces, using ANSYS®. IOP Conference Series: Materials Science and Engineering, 1256, 012014. https://doi.org/10.1088/1757-899X/1256/1/012014.

Dichev, D., Diakov, D., Dicheva, R. (2021). Method for increasing the accuracy of linear measurements based on a measurement-computational approach. AIP Conference Proceedings, 2505, 182583. https://doi.org/10.1063/5.0101084.

Dichev, D., Diakov, D., Zhelezarov, I., Valkov, S., Ormanova, M., Dicheva, R., Kupriyanov, O. (2024). A method for correction of dynamic errors when measuring flat surfaces. Sensors, 24(16). https://doi.org/10.3390/s24165154.

Malakov, I., Zaharinov, V. (2021). Choosing an Optimal Size Range of the Product “Pipe Clamp”. In R. Matoušek, J. Kudela (Eds.) Recent Advances in Soft Computing and Cybernetics. Studies in Fuzziness and Soft Computing. (pp. 197-213). Springer. https://doi.org/10.1007/978-3-030-61659-5_17.

Mitev, V., Malakov, I. (2024). Analysis of the Quality of Polymer Parts for Automatic Assembly. AIP Conference Proceedings, 3063(1), 060012. https://doi.org/10.1063/5.0195873.

Mitev, P. (2024). Development of a System for the Active Orientation of Small Screws. Engineering Proceedings, 70(55), 060017. https://doi.org/10.3390/engproc2024070055.

Tomov, P. (2017). Increasing the efficiency of automation of production processes by reporting the parameters of the parts’ flow. TEM Journal, 6(3), 484 – 487. https://doi.org/10.18421/TEM63-08.

Vassilev, V., Komarski, D. (2024). Retrofit of a Roundness Measuring Instrument. 34th International Scientific Symposium Metrology and Metrology Assurance. https://10.1109/MMA62616.2024.10817687.

Zach, T., Dudescu, M. (2021). The topological optimization and the design for additive manufacturing of a steering knuckle for formula SAE electric vehicle. 10th International Conference on Manufacturing Science and Education – MSE 2021, 343. https://doi.org/10.1051/matecconf/202134304011.