Anastasiia Plekhanova

Kocaeli University, (Türkiye)

Nevnihal Erdoğan

Kocaeli University, (Türkiye)

https://doi.org/10.53656/voc25-5-6-01

Abstract. Since the 1500s, Turkey has experienced over twenty earthquakes exceeding magnitude 7.0. The 2023 Kahramanmaraş earthquake, affecting 11 provinces and causing tens of thousands of deaths, stands as one of the century’s most devastating disasters. This tragedy renewed attention to the seismic resistance of building structures and materials. Wood, with its lightweight, flexible, and durable nature, offers strong potential for safe housing in seismic regions. Integrating industrial timber with modern construction techniques enables earthquake-resistant, sustainable, and environmentally responsible housing solutions. This study examines the technical properties of industrial timber and explores its application in contemporary residential systems, highlighting the first industrial timber housing project implemented in a seismic region of Turkey. By providing both theoretical insights and practical examples, it aims to support the wider adoption of timber construction and contribute to resilient, sustainable housing development in earthquake-prone regions.

Keywords: Wooden Housing, Earthquake Zone, Industrial Wood, Industrial Wood Production

- Introduction

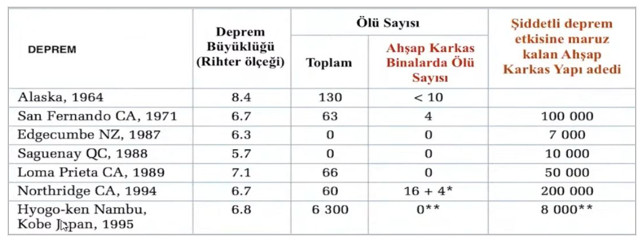

Nature provides humanity not only with a habitable environment and vital resources such as air, soil, and water, but also exposes societies to natural hazards that can result in destructive disasters. Among these, earthquakes pose the greatest threat to Turkey, which lies along one of the world’s most active seismic belts stretching from the Azores through the Mediterranean to Southeast Asia. The country has endured a long history of devastating earthquakes, most recently the catastrophic 2023 Kahramanmaraş event, which exposed the severe vulnerability of conventional construction systems. By contrast, evidence from other earthquake-prone countries (Institute for Research in Construction, Canada, 2023) demonstrates that even during strong seismic events, timber buildings show far lower collapse rates, with fatalities reported as zero or close to zero (Table 1).

Despite these advantages, timber construction in Turkey has long been neglected, with limited knowledge, education, and skilled labor in the field (Özer & Akbaş, 2021). Meanwhile, the construction sector worldwide is evolving to minimize ecological impacts and promote sustainable alternatives, and timber has re-emerged as a natural and renewable material of growing importance. In many developed countries, research initiatives and policy incentives have supported its wider use in housing, valued for both ecological and aesthetic qualities. Beyond sustainability, timber also offers critical advantages in seismic regions due to its lightweight, flexible, and durable nature, making it a reliable and resilient alternative for future construction.

- Earthquake and Architecture

Earthquakes, caused by the continuous movement of tectonic plates, are natural phenomena that occur frequently and can sometimes result in catastrophic destruction. During these events, shock waves generate high-amplitude horizontal forces on buildings, which are typically designed to resist vertical loads. This mismatch makes structures particularly vulnerable to lateral stresses, leading to damages ranging from minor surface cracks to complete collapse.

Scientific research and technological advancements in earthquake engineering have therefore introduced strategies to enhance building safety in tectonically active regions (Mazzolani & Dolce, 2009). Among these, material choice plays a decisive role. Lightweight and flexible materials such as wood have been shown to perform better under seismic loads due to their ability to absorb and dissipate energy more effectively than rigid, heavy materials.

In practice, seismic performance is influenced by both engineering-based reinforcements and the intrinsic properties of materials. For example, pendulum systems, stabilizing masses, and flexible foundations are widely employed in tall buildings to reduce sway; however, their effectiveness largely depends on the behavior of the structural materials themselves. Materials with high ductility, particularly wood, significantly improve the efficiency of such solutions by enhancing energy dissipation (Ceccotti et al., 2013).

At the same time, architectural decisions are equally critical. Irregular mass distribution, asymmetric geometry, or poorly placed load-bearing elements can negatively affect a structure’s seismic performance. For this reason, earthquake resistance must be integrated into architectural design from the earliest stages, ensuring that structural strategies and architectural choices complement one another. This collaborative approach not only enhances safety but also preserves functionality and aesthetic value.

Seismic design principles can be broadly categorized into three groups:

(1) General geometric form – the building’s three-dimensional shape, mass distribution, and orientation, which directly affect seismic response;

(2) Architectural details prone to failure – such as connections, discontinuities, or asymmetries that may weaken the system; and

(3) Non-structural elements – including walls, ceilings, and installations that can pose risks if inadequately designed (Alecci et al., 2019).

Finally, the seismic response of a building cannot be considered independently of the soil conditions beneath it. Soil type strongly influences the propagation of seismic waves, with soft soils often amplifying ground motions and placing higher stresses on structures. When the natural period of the soil coincides with that of the building, resonance effects may occur, particularly in tall buildings. Moreover, liquefaction in saturated sandy soils can cause settlement, tilting, or even collapse, regardless of the structural integrity above ground. Recognizing these risks, modern building codes such as TBDY 2018 require site-specific seismic design that accounts for soil behavior. In cases of weak or heterogeneous soils, advanced measures—such as seismic isolation systems or deep foundations – become necessary to ensure structural resilience and safety.

- Wooden Construction and Earthquake

The earthquake resilience of buildings depends not only on engineered reinforcements but also on the inherent properties of construction materials. Wood, in particular, excels due to its ductility and capacity to absorb and dissipate seismic energy; its fibrous cellular structure allows significant deformation before failure, enabling it to resist lateral forces more effectively than brittle materials (Smith et al., 2003). Its light weight further reduces the total mass of the structure, lowering inertial forces and decreasing seismic loads. Achieving optimal seismic performance requires balance: overly rigid systems may fail abruptly, while overly flexible ones can cause excessive swaying and occupant discomfort. Experimental studies indicate that massive timber buildings, especially when reinforced with metal connectors or combined with ductile materials such as steel, perform exceptionally under both vertical and horizontal loads by efficiently dissipating seismic energy.

From an architectural perspective, earthquake-resistant buildings must ensure structural safety while also addressing post-disaster needs, including shelter, logistics, and community recovery. Timber, particularly in industrially produced massive wood systems, meets these demands through high seismic performance, fire resistance, low carbon footprint, and recyclability. Prefabrication in factories ensures precision in joinery and connections, with pre-planned openings for utilities, which speeds up on-site assembly and reduces labor and errors. This approach also facilitates flexible interior layouts, allowing diverse material combinations and architectural variations that enhance both aesthetic and functional design. Furthermore, timber’s natural properties and ecological benefits help mitigate the negative environmental and psychological impacts in earthquake-affected regions, offering safe, sustainable, and quickly deployable housing solutions in response to urgent post-disaster building stock needs.

- Seismic Resistance of Timber Structures: Historical and Experimental Insights

Historical and contemporary earthquake records indicate that timber structures often outperform masonry and poorly detailed reinforced concrete buildings. Following major disasters such as the 1509 Istanbul and 1755 Lisbon earthquakes, timber-based systems (e.g., hımış, gaiola pombalina, casa baraccata, quincha, bahareque) were developed as flexible, lightweight, and resilient alternatives. Later observations from the 1894 Istanbul, 1994 Northridge, 1995 Kobe, 1999 Kocaeli, and 2023 Kahramanmaraş earthquakes further confirm that well-designed and maintained timber structures generally suffer less damage, whereas poor workmanship, decayed elements, or inadequate bracing can significantly reduce their performance.

Recent experimental research has reinforced these findings, particularly with modern engineered wood products such as CLT (Cross-Laminated Timber), LVL, and GLT. Large-scale shake table experiments in the US, Europe, and Turkey (e.g., UC San Diego’s full-scale CLT tests and TÜBİTAK-funded research in Trabzon) demonstrate that massive timber systems with advanced connections, self-centering walls, and hybrid solutions can withstand strong seismic forces with minimal damage while maintaining post-earthquake functionality (Ceccotti et al., 2013).

Figure 1. Earthquake shake table tests of a 20-story earthquake-resistant timber building at UC San Diego (URL-1)

Overall, both historical evidence and experimental results emphasize that the seismic performance of timber structures relies on design quality, material durability, and proper maintenance. By combining traditional construction knowledge with modern engineering technologies, timber emerges as a resilient, sustainable, and strategic material for earthquake-resistant architecture.

- Technological Solutions for Timber’s Weaknesses and Its Advantages

Modern technologies have redefined timber, addressing its natural weaknesses such as fire sensitivity, decay, insects, dimensional instability, and limited mechanical strength. Contrary to common prejudice, properly designed timber structures can achieve high fire resistance (up to 120 minutes), aided by treatments, coatings, and fire-protection systems (Kartal.2015). Decay and insect damage are controlled through drying techniques, thermal modification (e.g., Thermowood), and protective finishes. Timber elements are also easy to repair or replace, ensuring long service life and sustainability.

In structural terms, timber is lightweight yet strong, reducing seismic loads and foundation demands, which is critical in earthquake-prone regions. Engineered products like laminated timber provide predictable performance, and prefabrication (e.g., CNC-cut panels) speeds up construction while minimizing errors. Timber also offers high thermal insulation, acoustic comfort, and excellent carbon storage capacity—each cubic meter stores about 0.9 tons of CO₂ (UNECE/FAO, 2020).

As a renewable resource requiring low production energy, timber contributes to ecological balance and sustainable forestry when responsibly sourced. Historic wooden mosques in Turkey demonstrate its durability over centuries. Overall, with modern treatments and industrial processes, timber combines ecological, economic, structural, and aesthetic benefits, positioning it as a leading material for sustainable and earthquake-resistant architecture.

- Osmaniye Timber Housing Project

Following initiatives such as the 2022 “Timber Use Promotion Workshop” in Ankara, Turkey launched its first collective timber housing project in Osmaniye, a seismic zone. Commissioned by the General Directorate of Forestry (OGM), designed by NMK Architecture, and constructed by NASWOOD, the project aims to serve as a pilot for future timber construction regulations.

The development consists of three residential blocks (3 floors + basement) forming a site with 36 apartments (3+1 units), as well as shared facilities such as parking, sports areas, playgrounds, and green spaces. To enhance safety, the project adopts a hybrid system: concrete is used in basements, cores, and shared spaces, while living areas are built with industrial timber. Each block has a footprint of 740 m², with a total site area of 2200 m².

Timber was chosen for its fast construction, light weight, seismic resilience, natural insulation, and environmental benefits. The project not only provides comfortable, healthy, and sustainable housing but also represents a significant step toward integrating timber into Turkey’s construction sector and improving earthquake-resistant, eco-friendly design practices.

6.1. Use of Engineered Timber in the Osmaniye Housing Project:

The Osmaniye OGM Housing Project was designed to promote both environmental sustainability and the wider use of timber in residential construction. Engineered wood was chosen as the primary material for structural elements such as columns and beams, as well as for non-structural components like walls, roofs, and window frames, ensuring strength, durability, and energy efficiency.

Exterior façades feature timber cladding to highlight natural aesthetics, while OSB panels improve insulation and resilience. Inside, timber panels are used in corridors, with MDF furniture and laminated wood surfaces in apartments, creating a warm, natural interior atmosphere. This integrated approach combines structural performance, ecological benefits, and architectural aesthetics, positioning timber as a key material for modern housing design.

For the main load-bearing system, glulam spruce (imported from Russia and Ukraine) was used in large cross-sections for columns and beams. The timber was kiln-dried to 10 – 12% moisture to ensure bonding quality and prevent cracking, then planed, calibrated, defect-checked, and classified before lamination. Long members (up to 8.87 m) were produced using finger-jointing, and MUF adhesives were applied, with elements cold-pressed to create strong glulam blocks.

CNC machining enabled precise cutting, drilling, and detailing for connections, significantly improving assembly speed, structural accuracy, and seismic performance. These details ensured rigidity and energy dissipation in dynamic loads such as earthquakes. Finished elements were tested, labeled for traceability, packaged against moisture/damage, and delivered in assembly order (columns, beams, floors, walls, roof).

The production process demonstrates a high level of engineering precision, quality control, and sustainability, enhancing not only structural capacity but also ease of construction and seismic resilience. Overall, the project represents a modern and successful application of glulam technology in Turkey’s timber construction sector.

6.2. Assembly Process of the Osmaniye OGM Timber Housing Project

The Osmaniye OGM timber housing project demonstrates how prefabricated industrial timber systems can shorten construction time, reduce costs, and improve quality. Structural elements were produced in a factory with CNC precision, classified by assembly order, and transported to site, minimizing labor and errors.

Construction began with raft foundations, chosen despite timber’s lightness due to the site’s seismic risk, need for a basement, and safety considerations. Parallel to foundation works, timber elements were engineered, digitally processed, and manufactured in Naswood’s facilities.

On site, assembly followed a systematic sequence:

– March 2024 – timber columns (8.8 m glulam spruce) were anchored to the foundation;

– columns and beams formed the load-bearing frame over four months;

– later, prefabricated floors, partition walls, and roof structures were installed (April – September 2024);

– finishing works included façades, windows, mechanical systems, and interior fittings.

The project applied a hybrid system, combining reinforced concrete (basement, cores, foundations) with timber superstructure, ensuring both rigidity and sustainability. Prefabrication and CNC machining provided speed, precision, and seismic safety, positioning this development as a pioneering example of modern hybrid timber construction in Turkey.

6.3. Seismic Design Principles of the Osmaniye Timber Housing Project

The hybrid timber–concrete system was specifically designed for earthquake resilience. Timber’s light weight and elasticity reduce lateral forces and allow controlled deformation under seismic loads. Symmetrical placement of columns, orthogonal load-bearing arrangements, and balanced openings further enhance stability.

Connections were designed to be energy-dissipating through CNC-precision joinery combined with metal plates and bolts. Approximately 850 m³ of timber (~382.5 tons) forms the superstructure, optimized for flexibility rather than rigidity, ensuring a safe response during earthquakes.

Architecturally, the project addresses post-disaster needs by providing rapid assembly potential and flexible interior layouts. Prefabrication allows different combinations of timber types and building configurations, creating diverse and adaptable residential units. Timber’s natural aesthetics, warmth, and ecological qualities help mitigate negative environmental and psychological impacts in earthquake-affected areas, promoting occupant comfort and well-being.

- Conclusions and summary

Turkey’s seismic history and the devastating consequences of the 2023 Kahramanmaraş earthquake highlight the urgent necessity of rethinking material choices and construction practices. This study has shown that industrial timber, when integrated with modern engineering and architectural strategies, offers significant advantages for seismic resilience, sustainability, and housing quality. With its lightweight, ductile, and energy-absorbing nature, wood reduces earthquake-induced forces, while prefabricated technologies enhance construction precision, speed, and quality control.

The OGM Osmaniye Timber Housing Project stands out as one of the first hybrid systems (reinforced concrete–industrial timber) implemented in Turkey and, being realized in a high seismic risk zone, demonstrates that timber structures can be a strong alternative for earthquake resistance. The building, constructed with approximately 850 m³ of timber, achieved structural precision and reliable performance under seismic loads through CNC-fabricated joints and metal connection details that ensured durability and integrity. Environmentally, it contributed to sustainability by storing around 701 tons of CO₂, significantly reducing its carbon footprint. Beyond structural safety, the design emphasized the natural texture and warm atmosphere of timber, combined with passive climate control features, to create a comfortable, aesthetic, and user-centered living environment. As a pioneering example, it provides both a technical reference and a practical model for future timber housing initiatives in seismic regions.

Ultimately, the integration of industrial timber into Turkey’s housing sector represents not only a structural and technological innovation but also a cultural and environmental shift toward more resilient, ecological, and community-centered construction. Continued research, policy support, and professional training will be essential to expand its application and unlock timber’s full potential in shaping earthquake-resistant and sustainable urban development.

REFERENCES

Akbaş, A.; Yilmaz, T. (2023). Evaluation of the 2023 Kahramanmaraş earthquakes: Seismological and engineering aspects. Journal of Earthquake Engineering, 27(3), 145 – 162.

Alecci, V.; De Stefano, M. (2019). Building irregularity issues and architectural design in seismic areas. Frattura ed Integrità Strutturale, 47, 161 – 168.

Burcu Kartal. (2015). Yapılarda Ahşap Kullanımı ve Çağdaş Yapı Teknolojisinde Ahşap Kullanımı. Yüksek Lisans Tezi, Haliç Üniversitesi, Fen Bilimleri Enstitüsü, İstanbul, 413520.

Büyüksaraç, A., Aydinoğlu, N. (2020). Seismic hazard and risk assessment in Turkey: Current perspectives. Natural Hazards, 103(2), pp. 2189 – 2212. ISSN 0921-030X.

Ceccotti, A., Sandhaas, C., Okabe, M., Yasumura, M., Minowa, C., Kawai, N. (2013). SOFIE project: 3D shaking table test on a seven-storey full-scale cross-laminated timber building. Earthquake Engineering & Structural Dynamics, 42(13), 2003 – 2021. ISSN 0098-8847.

Çavuş, M., Özmen, B. (2019). Deprem mühendisliğinde yapı malzemelerinin davranışı. İstanbul: İTÜ Yayınları.

Erdik, M., Durukal, E. (2008). Earthquake risk and mitigation in Istanbul. Natural Hazards, 44(2), 181 – 197. ISSN 0921-030X.

Fukuyama, H., Sugano, S. (2000). Japanese seismic design of timber structures. Progress in Structural Engineering and Materials, 2(3), pp. 303 – 311. ISSN 1365-0556.

Gülkan, P., Sözen, M. A. (1974). The 1970 Gediz earthquake: An engineering analysis. Earthquake Engineering & Structural Dynamics, 3(2), 145 – 152. ISSN 0098-8847.

Institute for Research in Construction (IRC). (2023). Timber construction performance in seismic regions. Ottawa: National Research Council of Canada.

Kramer, S. L. (1996). Geotechnical earthquake engineering. Upper Saddle River, NJ: Prentice Hall. ISBN 0-13-374943-6.

Mazzolani, F. M., Dolce, M. (2009). Seismic design principles in architecture and engineering. London: CRC Press. ISBN 978-0-415-41642-2.

NMK Architecture. (2023). Osmaniye Timber Housing Project design report. Ankara: NMK Architecture.

OGM – General Directorate of Forestry. (2022). Timber Use Promotion Workshop Report. Ankara: Republic of Türkiye Ministry of Agriculture and Forestry.

Özer, E., Akbaş, S. (2021). Sustainable timber housing in seismic zones: A review of material and design strategies. Journal of Sustainable Architecture and Civil Engineering, 31(2), 78 – 93. ISSN 2029-9990.

Smith, I., Landis, E., Gong, M. (2003). Fracture and fatigue in wood. Chichester: Wiley. ISBN 978-0-470-84492-7.

TBDY. (2018). Türkiye Bina Deprem Yönetmeliği. Ankara: T.C. Çevre, Şehircilik ve İklim Değişikliği Bakanlığı.

Waugh, A. (2019). Wood: New directions in timber architecture. London: Thames & Hudson. ISBN 978-0-500-52148-6.

Anastasiia Plekhanova, Master’s student

ORCID iD: 0009-0001-2127-9595

Kocaeli University

Türkiye

E-mail: anastasiiaplekhanova16@mail.com

Prof. Dr. Nevnihal Erdoğan

Kocaeli University

Türkiye

>> Изтеглете статията в PDF <<