Nataliya Koleva

ORCID iD: 0000-0003-3564-7720

Technical University of Sofia, Bulgaria

Siyka Demirova

ORCID iD: 0000-0001-6557-7407

Technical University of Varna, Bulgaria

https://doi.org/10.53656/igc-2024.17

Pages 196-206

Abstract. The issue of business process sustainability is becoming increasingly important for modern businesses, encouraging industrial enterprises to seek effective ways for the long-term preservation of resources and the minimization of negative environmental impacts—in other words, transforming current business models into sustainable ones. Re-manufacturing, or the process of restoring and recycling products and materials, plays a key role in this context. Innovations in re-manufacturing offer new opportunities to create sustainable business models that not only meet environmental standards but also provide economic and social benefits. The aim of this article is to explore the significance of re-manufacturing in creating sustainable and competitive businesses in the modern economy, while also addressing the challenges and barriers to implementing reproduction practices and offering practical guidelines for overcoming them. In this regard, the article presents a comprehensive analysis of current trends and innovations in the field and discusses how re-manufacturing processes can be integrated into business strategies to achieve greater efficiency and environmental responsibility.

Keywords: Sustainability; Re-manufacturing; Circular Economy; Business Processes; Industrial Enterprises

JEL: M11, Q01, Q56

- Introduction

The problems of “Sustainability” and “Sustainable Development” have been widely studied and discussed in scientific circles since the beginning of the 1990s (Sarkar et al., 2022; Barbosa et al., 2014; Hajian & Kashani, 2021; Lélé, 1991 ; Mebratu, 1998; Penchev & Pencheva, 2017). If we follow the development of the concept of “Sustainable Development”, it can be seen that it gradually expands its context and becomes a “global continuous process that seeks to balance the social, ecological and economic norms and values of humanity” (Dimitrov, 2018). For the first time, the topic of “Sustainable Development” gained public and international resonance in 1972. The first definition of this concept emphasized „meeting the needs of the present generation without threatening the ability of future generations to meet their needs“ (Keeble, 1988). Subsequently, as stated in (Dimkow, 2019a), opportunities are sought and research is conducted to support a more detailed elucidation of the essence of this concept through the determination of possible indicators to characterize sustainable economic activities (Searcy, 2014; Searcy, 2012; Ziegler, 2009). In the definition described in a UN document, which gives a broader understanding of this concept: “sustainable development is that which satisfies the basic needs of people, preserves, protects and restores the health and integrity of the Earth’s ecosystem, does not threaten the ability to meet the needs of future generations and does not exceed the long-term capacity limits of the ecosystem” (Dimitrov, 2018). An interesting approach that attempts to achieve a clearer and more comprehensive understanding of the concept of sustainable development is proposed by Elkington (1997) with the so-called Triple-Bottom-Line – TBL, where the understanding of “Sustainability” is based on the thesis that the success of enterprises does not depend only on their financial condition, but also on the social (ethical) and ecological well-being of their environment. It can be summarized that the processes of realizing and achieving sustainable development have a very complex nature and are a function of the positive efforts of all stakeholders. Of course, the business community ranks here among the stakeholders with the potential for the most serious contribution to achieving sustainability goals.

Building a sustainable business system is one issue that is invariably the focus of attention for the management of any industrial enterprise (IE). Given that enterprises are a system object, it can logically be argued that their existence, development and sustainability is based on the positive development and balance of the total value of its elements and assets. Achieving this balance is proving to be a difficult task, as enterprises are currently facing a number of challenges and achieving sustainability, within the dynamic environment in which they operate and develop, becomes a continuous process of timely adaptation of ongoing business processes in relation to the requirements of the market and the expectations and attitudes of the customers regarding the value of the offered products and/or services. However, this approach only helps them not to lose their market positions, but not in fulfilling the sustainability goals in their full scope and context. Also, the previous behavior of producers and consumers is an indicator that the value concept of sustainable development has not been adopted and imposed, which is a prerequisite for unsustainability and a threat to the balance in the ecosystem, and also to the existence of society. In this direction, IEs are really under serious pressure, which has been increasing in recent years due to the high popularity of the so-called ESG (Environmental, Social & Governance) policies. Moreover, in 2025 the first reports will be made according to the new regulatory framework. In this sense, companies need to build a new vision for the implementation of their activity, which on the one hand adds value for the producer-consumer sides, but without making a compromise with the effects that is left on nature and the future, and the people lives. The process of successful sustainable business model creating requires resolute management intervention and responsible consumption and production behavior by society (Dimkow, 2019a). It is necessary to think about transforming production processes with a view to emphasizing the control of emissions released into the atmosphere, extending the life of products, reusing products, recycling waste, etc. This transformation is not a easy task. Although on a prima facie of it these are mainly monitoring and control procedures and are part of the last phases of the production process (Todorova, 2016), the changes must be much deeper and be rooted in the values of the enterprise, discussed with employees and users, so that they can become a norm that is imposed and remains permanent.

In practice, in order to achieve the goals of “Sustainable Development”, for IE is important to be able to create a closed loop of material flows, and of course the consumer and society as a whole will play a decisive role of this. An opportunity to achieve this is the recovery of products or the remanufacturing of products, which is essentially also embedded in the main idea of the so-called “Circular Economy”. The “Circular Economy” focuses on the entire value chain (from the extraction of raw materials, through their transformation and production, distribution and consumption/exploitation) and is based on recovery and regeneration, not on the consumption of resources (Dimkow, 2019b). To achieve this, the positive participation of all participants in the value creation process is necessary. The aim of this paper is to explore the importance of remanufacturing in creating a sustainable and competitive business in the modern economy, while addressing the main challenges and barriers to the implementation of remanufacturing practices and offering practical guidance to overcome them. In this regard, the article presents a comprehensive analysis of current trends and innovations in the field, as well as the experience of Bulgarian IEs, and also discusses how remanufacturing processes can be integrated into business strategies to achieve greater efficiency and environmental responsibility.

- The Remanufacturing Process

The economic, social and environmental pressures to which industrial enterprises are subjected encourage them to seek effective ways of long-term conservation of resources and minimization of negative environmental impacts (Dimkow, 2019b; Nikolov, 2019; Ijomah, 2010), while at the same time they provide economic and social benefits. According to the authors, remanufacturing plays a key role in this context. It should be considered not only as a necessity, but also as part of the strategy of industrial enterprises to achieve a competitive advantage. In addition, given the increasing monitoring and control of businesses’ environmental impact, they are forced to focus on sustainable practices that include reusing materials, reducing waste, and implementing circular economy models. These approaches can not only reduce the environmental footprint, but also help to optimize costs and improve the efficiency of production processes.

2.1. State of the art

Remanufacturing is defined as a technological process that is carried out on an out-of-use component or end product/product in order to return it as new or with better performance (to restore its functionality) and in fulfillment of the relevant requirements and standards for qualitatively, so that it is used for at least one more life cycle (CRR, 2007; Dimkow, 2019b; Golinska & Kuebler, 2014; Kurilova-Palisaitiene et al., 2018; Steinhilper, 1998; Sundin, 2002; Aksoy & Gupta, 2005). An analysis of this definition can bring to the fore some key benefits that remanufacturing can generate for businesses and society. Broadly, they can be classified into three main groups (Sarkar et al., 2022; Paterson et al., 2017; Ijomah, 2010):

– Economic benefits, which are mainly related to cost reduction due to the reuse of components.

– Environmental benefits, which are related to reducing the number of landfills, as well as preventing air pollution (Gray & Charter, 2007), which is a consequence of reducing carbon emissions and reducing industrial waste in general.

– Social benefits, which refer to the creation of new jobs, necessary to ensure the process of repeated production and improve the reputation of the enterprise as a socially responsible and sustainable entity. This is an opportunity to court, attract and retain a new target group of consumers for whom environmental responsibility is a price.

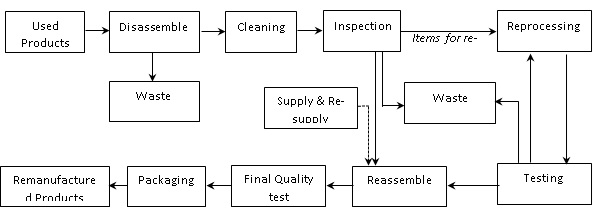

A clearer idea of the nature of the remanufacturing process is given by the analysis of fig. 1, on which the General flow chart of a remanufacturing process is presented.

Figure 1. General flow chart of a remanufacturing process Source: Amezquita et al. (1995); Golinska (2013)

It can be said that the remanufacturing process is organized, implemented and managed as a standard transformation/production process, which is characterized by its main phases and operations. The peculiarity here is that in structural terms the process of re-production can be much more complex than that of creating new products. This is an issue that requires careful consideration, as it may dominate a company’s decision to remanufacture.

2.2. Aspects of the Complexity of Remanufacturing Implementation

The remanufacturing process implementation requires a very clear understanding of its nature and essence. Undoubtedly, the measures related to the integration of the remanufacturing process into existing business models is a complex task and requires a thorough risk assessment (Nikolov, 2023). As already indicated, the process shown in fig. 1 can be compared to a standard production process, but this is only at first glance. The essential difference lies in the first two phases of the process, “removal of already used products” and “Disassembly”. They are the main source of a high degree of uncertainty, risk and complexity. This is because, for different types of products, it is difficult to predict with sufficient accuracy the moments of arrival and the quantities of already used products that need to undergo remanufacturing. This is a circumstance that significantly complicates the objective formation of a view on basic indicators such as: operating times for individual operations, volume of used products/components for remanufacturing (Dimkow, 2019b; King et al., 2006). This high degree of uncertainty gives rise to serious problems in production planning and organization, as well as in terms of inventory control. All this is a clear prerequisite for reducing the overall efficiency of the virtual remanufacturing system and, in practice, is a major barrier to the implementation of remanufacturing. The last one emphasizes the needs of constructed policy on the part of businesses, which is applied consistently so that consumers can also recognize it. Which turns the consumer into a lasting and important partner and participant in the production of value and the reproduction process.

Regarding the “Disassembly” phase, there the attention is directed to the questions related to the construction of the new products with their architecture, since it turns out to be of crucial importance for the possibility for remanufacturing process implementation. In this respect, the “suitability of the product for remanufacturing” can be defined as the main indicator for evaluating the feasibility of the remanufacturing process. Regardless of the complex nature and challenges associated with remanufacturing process design, it is important to highlight its benefits and serve as a motivator for industrial enterprises in their quest to become socially responsible entities.

It can be summarized that remanufacturing is becoming a matter of strategic importance for enterprises and presents them with a serious challenge, as the depth of transformation that needs to be carried out in existing business models to go along the path of sustainable development.

- Remanufacturing for Sustainability: The Case of Bulgarian Industrial Enterprises

3.1. Methodology Aspects

In order to establish the experience of Bulgarian IEs in the implementation of remanufacturing processes, a survey was conducted among 43 enterprises from all over the country. Top managers were selected as respondents, given that the issue is of strategic importance. A survey card was prepared to collect the empirical data and was sent by e-mail to the respondents. In addition, the chosen method of collecting the empirical information was accompanied by an interview at the workplace. The research was conducted in the period 10.03.2024 ÷ 27.06.2024. The volume of the studied industrial enterprises cannot claim to be representative, but in the opinion of the authors the results are indicative of the activity and progress of Bulgarian industrial enterprises in the implementation of measures for re-production and other similar value-adding processes for the implementation of sustainable development goals.

3.2. Main Results

As already mentioned, the research covered a total of 43 industrial enterprises, of which: 49% are located in Sofia, 30% – in large cities and 21% – in small towns. Of the research enterprises: 29% are large enterprises, 36% are medium-sized, 26% are small and 9% are micro-enterprises.

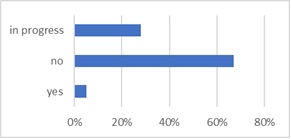

It was found that for a large part of the enterprises (84%) “sustainable business” is equivalent to “green business” and is reduced to carrying out activities related to recycling of office supplies, more reasonable consumption and most already using energy from renewable sources. It is also striking (fig. 2) that a relatively large percentage of enterprises are defined as not ready (67%) to fulfill the sustainable development goals by the first reporting period in 2025. Nevertheless, the fact that 28% are in the process of building a vision in this direction is positive.

Figure 2. Readiness to Implement the Sustainable Development Goals

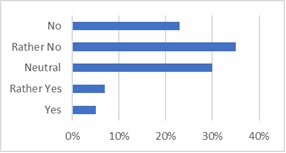

In terms of decisions to carry out repeated production, the majority of enterprises refrain from this practice now – fig. 3.

Figure 3. Аre you considering implementing remanufacturing as a sustainable practice?

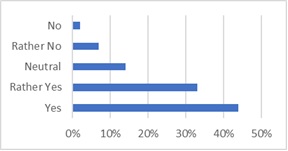

A large part of the surveyed enterprises (77%) define the measures related to the integration of repeated production as very labor-intensive and requiring a serious investment, which they define as a serious obstacle – fig. 4.

Figure 4. Do you consider the amount of remanufacturing investment as a barrier?

A positive impression is made by the relatively large number of enterprises (28%) that already recycle waste or are considering the introduction of similar activities such as recovery, repair, etc. According to the authors, this can be a good first step on the road to sustainability.

It can be seen that enterprises have a long way to go to achieve the target efficiency of sustainable production development. It is positive that they are aware of the prospects for their expansion and, regardless of the challenges, find motivation and consider the restructuring and redesign of existing business models into more sustainable ones.

- Summary and Conclusions

This paper presents a discussion on the importance of remanufacturing in creating a sustainable and competitive business in the modern economy. Some of the main obstacles to the implementation of remanufacturing practices were discussed, mostly related to the structure of the remanufacturing process. The results of an empirical study of the maturity of Bulgarian industrial enterprises with regard to the concept of multiple productions and the implementation of sustainable development goals are also presented and analyzed.

It can be summarized that currently remanufacturing should be considered not only as a necessity, but also as part of the strategy of industrial enterprises to achieve a competitive advantage. Given the increasing scrutiny of businesses’ environmental impact, they are forced to focus on sustainable practices that include reusing materials, reducing waste and implementing circular economy models. These approaches not only reduce the environmental footprint, but also optimize costs and improve the efficiency of production processes.

The article also highlights the importance of strategic planning and innovative approaches needed to adapt to changing market conditions and consumer demands. Industrial enterprises must develop long-term strategies that integrate reproduction into the overall business model. This includes investing in new technologies, training employees, collaborating with partners and suppliers and, last but not least, rethinking the organizational culture to successfully establish business models and realize high added value.

In their future work, the authors set themselves the task of studying and proposing a system of factors affecting the effectiveness of the implementation of remanufacturing for different industrial sectors, as well as to explore in depth the main risks that accompany this undertaking.

Acknowledgement

The authors would like to thank the Research and Development Sector at the Technical University of Sofia for the financial support.

REFERENCES

Aksoy, H. K. & Gupta. S. M. (2005). Buffer Allocation Plan for a Remanufacturing Cell. Computers and Industrial Engineering, 48(3), 657 – 677. https://doi.org/10.1016/j.cie.2003.03.007

Amezquita, T., Hammond, R., Salazar, M. & Bras, B. (1995). Characterizing the Remanufacturability of Engineering Systems. In Proceedings of 1995 ASME Advances in Design Automation Conference (pp. 271 – 278). Boston, Massachusetts, MA, USA.

Barbosa, G. S., Drach, P. R., & Corbella, O. D. (2014). A Conceptual Review of the Terms Sustainable Development and Sustainability. Journal of Social Sciences, 3(2), 1.

Centre of Remanufacturing and Reuse (CRR). (2007). An Introduction to Remanufacturing.

Dimitrov, K. (2018). Preconditions for Sustainable Development of the Enterprise by Development of Leadership Capacity. Management and Sustainable Development, 68(1), 42 – 50. [in Bulgarian]

Dimkow, S. (2019a). Social Responsible Manufacturing. Avangard Prima Publisher. [in Bulgarian]

Dimkow, S. (2019b). Remanufacturing. Avangard Prima Publisher. [in Bulgarian]

Elkington, J., (1997). Cannibals with Forks: The Triple Bottom Line of 21st Century Business. Capstone.

Golinska, P. (2013). Proposal for Materials Mangement Assesment in Remanufacturing Facility. International Journal of Logistics and SCM Systems, 7(1), 31 – 38.

Golinska, P., & Kuebler, F. (2014). The Method for Assessment of the Sustainability Maturity in Remanufacturing Companies. Procedia CIRP, 15, 201 – 206. https://doi.org/10.1016/j.procir.2014.06.018

Gray, C., & Charter, M. (2007). Remanufacturing and Product Design: Designing for the 7th generation. Centre for Sustainable Design, SEEDA.

Hajian, M., & Kashani, S. J. (2021). Evolution of the Concept of Sustainability. From Brundtland Report to Sustainable Development Goals. In C. M. Hussain, J. F. Velasco-Muñoz (Eds.), Sustainable Resource Management: Modern Approaches and Contexts (pp. 1– 24). Elsevier. https://doi.org/10.1016/B978-0-12-824342-8.00018-3

Ijomah, W. L. (2010). The Application of Remanufacturing in Sustainable Manufacture. Proceedings of the Institution of Civil Engineers-Waste and Resource Management, 163(4), 157 – 163. https://doi.org/10.1680/warm.2010.163.4.157

Keeble, B. (1988). The Brundtland report: ‘Our Common Future. Medicine and War, 4(1), 17– 25.

King, A. M., Burgess, S. C., Ijomah, W., & Mcmahon, C. A. (2006). Reducing Waste: Repair, Recondition, Remanufacture or Recycle? Sustainable Development, 14(4), 257 – 267. https://doi.org/10.1002/sd.271

Kurilova-Palisaitiene, J., Sundin, E., & Poksinska, B. (2018). Remanufacturing Challenges and Possible Lean Improvements. Journal of Cleaner Production, 172, 3225 – 3236. https://doi.org/10.1016/j.jclepro.2017.11.023

Lélé, S. M. (1991). Sustainable Development: A Critical Review. World Development, 19(6), 607 – 621. https://doi.org/10.1016/0305-750X(91)90197-P

Mebratu, D. (1998). Sustainability and Sustainable Development: Historical and Conceptual Review. Environmental Impact Assessment Review, 18(6), 493 – 520. https://doi.org/10.1016/S0195-9255(98)00019-5

Nikolov, B. (2023). Main Pillars Building Up the Risk Frame of Industry 4.0 Implementation in the Enterprises in Bulgaria. Economic Studies (Ikonomicheski Izsledvania), 32(7), 77 – 92.

Nikolov, B. (2019). Possibilities and Restrictions in Forming and Development of the Innovative Potential of the Enterprises in Bulgaria. International Scientific Journal “Innovations”, 5(1), 6 – 8.

Paterson, D. A., Ijomah, W. L., & Windmill, J. F. (2017). End-of-life Decision Tool with Emphasis on Remanufacturing. Journal of Cleaner production, 148, 653– 664. https://doi.org/10.1016/j.jclepro.2017.02.011

Penchev, P. & Pencheva, R. (2017). Sustainable Development – Theoretical and practical Aspects. Year-book of D. A. Tsenov Academy of Economics – Svishtov, 120, 69 – 118.

Sarkar, B., Ullah, M., & Sarkar, M. (2022). Environmental and Economic Sustainability Through Innovative Green Products by Remanufacturing. Journal of Cleaner Production, 332, 129813. https://doi.org/10.1016/j.jclepro.2021.129813

Searcy, C. (2012). Corporate Sustainability Performance Measurement Systems: A Review and Research Agenda. Journal Business Ethics, 107(3), 239-253. https://doi.org/10.1007/s10551-011-1038-z

Searcy, C. (2014). Measuring Enterprise Sustainability. Business Strategy and the Environment, 25(2), 120– 133. https://doi.org/10.1002/bse.1861

Steinhilper, R. (1998). Remanufacturing: The Ultimate Form of Recycling. IRB-Verlag.

Sundin, E. (2002). Design for Remanufacturing from a Remanufacturing Process Perspective. [Dissertation thesis No. 944, Department of Mechanical Engineering, Linkopings Universitet]. Linköping Studies in Science and Technology: Thesis, 944.

Todorova, T. (2016). Theory of Constraints and Project Management (Joint Application in Organizational Management). Softtreid Publisher. [in Bulgarian]

Ziegler, R., (2009). The Politics of Operationalisation: Sustainable Development and the Eco-space Approach. Environmental Politics, 18(2), 163 – 181. https://doi.org/10.1080/09644010802682544