Afrim Gjelaj

ORCID iD: 0000-0002-6155-7596

FME University of Pristina, Kosova

Besart Berisha

Scopus ID: 57201726147

FME University of Pristina, Kosova

Albi Macula

FME University of Pristina, Kosova

https://doi.org/10.53656/adpe-2025.02

Pages 23-31

Abstract. Accurate estimation of assembly costs is essential for enhancing manufacturing efficiency and competitiveness. This study investigates the application of the 3C (Crafts Cost Calculator) for modeling and optimizing the costs associated with welding and mechanical fastening in assembly operations. Optimization of bolted joints is essential not only for mechanical integrity but also for reducing system cost and weight (Croccolo, 2023). In contrast, welding processes, although structurally rigid, require precise control of parameters to ensure quality and minimize waste. Taguchi and gray relational analysis can significantly improve the quality and reliability of stud welding (Çinay, 2023), while temperature and time strongly influence weld performance and cost (Birtha et al., 2023).

Through the 3C platform, this research models and compares the labor, equipment, and operational costs of both methods, integrating real manufacturing data to produce practical insights. Co-optimization of planning and supply chain decisions can substantially impact overall production cost (Nwodu et al., 2022), highlighting the broader implications of integrating digital cost modeling tools early in the design process.

The findings offer a structured approach for manufacturers to select cost-effective assembly strategies and demonstrate the value of the 3C tool in supporting design and operational decision-making.

Keywords: cost estimation; assembly; automated calculation; optimization; cost analysis; welding and mechanical fasteners

- Introduction

In modern manufacturing, cost optimization is not only a matter of competitive advantage but also a necessity for operational sustainability. One of the most critical contributors to production cost is the assembly phase, where welding and mechanical fastening (e.g., bolts and screws) are widely used. The selection between these methods impacts not only structural integrity but also labor time, equipment requirements, and long-term maintenance. Recent research has emphasized the technical and financial implications of assembly choices. As (Croccolo et al., 2023; Arifaj et al., 2024) point out, proper optimization of bolted joints can reduce both material use and overall system cost. Similarly, welding operations, while offering strong and often permanent joints, introduce complexities in terms of energy usage, process control, and skilled labor (Çinay et al., 2023; Birtha et al., 2023).

Moreover, (Nwodu et al., 2022) highlight how coordinated planning of assembly operations and supply chain configuration can lead to significant cost reductions.

To address the need for transparent and adaptable cost estimation tools, this study employs the 3C (Crafts Cost Calculator), a spreadsheet-based digital platform developed to analyze production costs in real time. This research paper focuses on evaluating and comparing the cost implications of welding and mechanical fasteners using the 3C tool, offering insights that support engineers and managers in making cost-effective assembly decisions early in the design phase.

- Methodology

This chapter outlines the methodology employed to evaluate and compare the cost efficiency of two assembly techniques (welding and mechanical fasteners) through the use of the 3C (Crafts Cost Calculator) tool. The approach involves data collection, cost modeling, and analysis using an Excel-based form designed to estimate manufacturing costs with a focus on labor, material, and process-specific parameters.

2.1. Overview of the 3C tool

The 3C (Crafts Cost Calculator) is a Microsoft Excel-based system designed to calculate manufacturing and assembly costs efficiently. It allows users to input design parameters and production data to generate automatic estimates of labor hours, material usage, process steps, and associated costs. In this study, the 3C tool is enhanced with assembly-specific logic to support real-time comparison between welding and bolted assemblies.

2.2. Case study assemblies

Two comparable mechanical assemblies were selected for cost analysis:

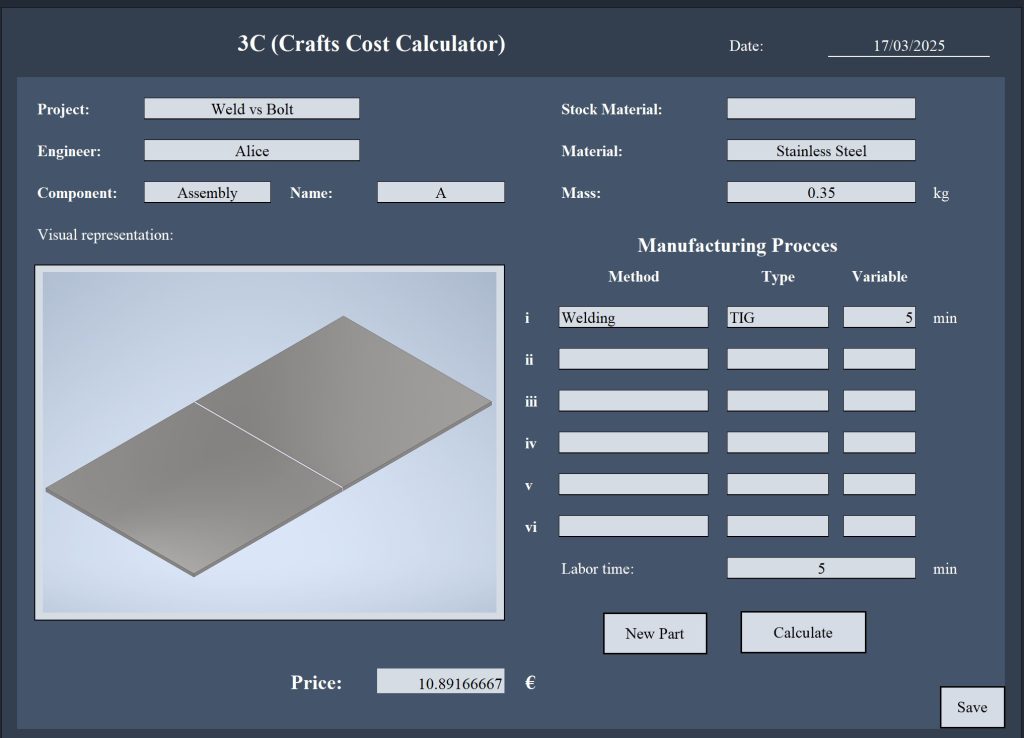

- Assembly A (Welded Assembly): A steel structure composed of rectangular Sheets joined using standard TIG welding techniques. (Fig. 1).

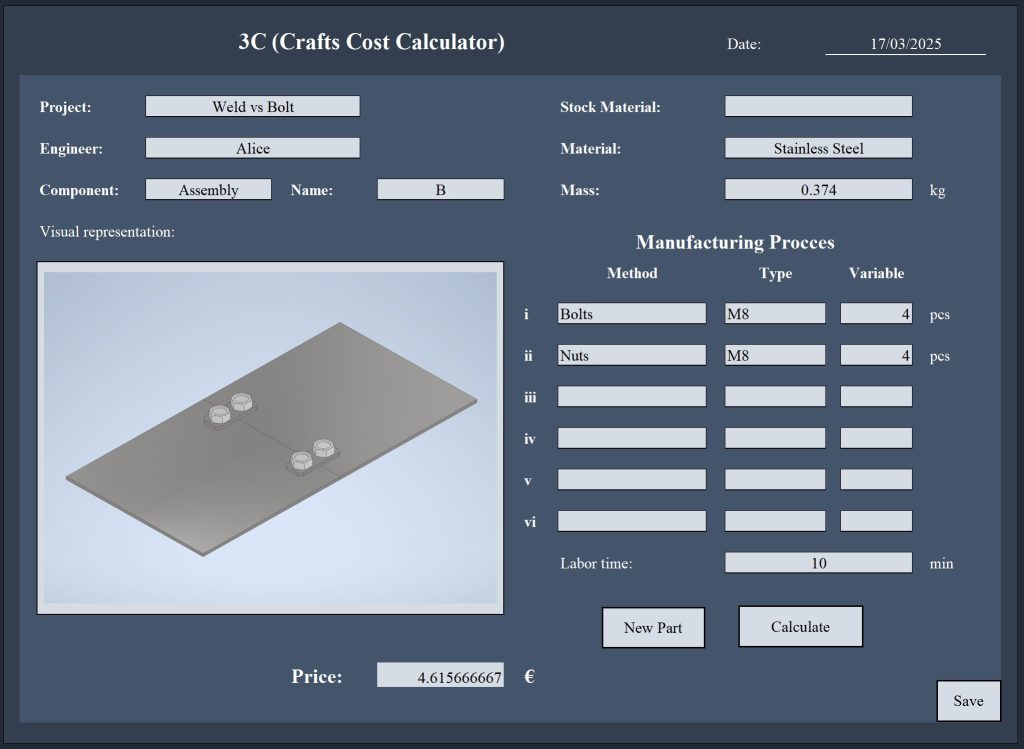

- Assembly B (Bolted Assembly): The same structure assembled using M8 bolts and flanged joints, modeled to require no welding. (Fig. 2).

Figure 1. Welded Assembly

Both assemblies were modeled in CAD software and had identical structural functions, dimensions, and load capacities. Only the joining method was varied.

Figure 2. Bolted Assembly

2.3. Cost estimation procedure

The cost estimation process was executed in the following steps for each assembly (Table 1):

- Design Input: All dimensional and geometric data were extracted from CAD models and entered into the 3C interface.

- Material Definition: Material types and quantities were defined for both versions, considering raw steel for welding and pre-drilled flanged steel for bolting.

- Labor Estimation:

- For the welded version, time per weld, joint preparation, and inspection were calculated using reference data (e.g., [1], [2]).

- For the bolted version, drilling time, bolt insertion, and torque application were estimated.

- Cost Calculation: Using embedded formulas in the 3C tool, the total cost was calculated for each assembly.

Table 1. Price estimation for A&B

| 3C Archives | ||||

| Name | Manufacturing process | Price(€) | ||

| i | ii | iii | ||

| A | Welding | – | – | 10.89 |

| B | Bolts | Nuts | – | 4.61 |

- Application-specific considerations for welding and bolting

3.1. Structural requirements

The choice between welding and bolting is heavily influenced by the structural demands of the application:

- Welding: Welded joints are typically stronger and more rigid due to the continuous fusion of materials. This makes welding ideal for applications requiring high structural integrity, such as load-bearing frames in heavy machinery or bridges.

- Bolting: Bolted joints are less rigid but offer modularity and ease of disassembly. They are preferred in applications where frequent maintenance or adjustments are required, such as modular structures, equipment enclosures, or temporary installations.

3.2. Environmental factors

Environmental conditions can dictate the suitability of each method:

- Corrosion Resistance: Welded joints are prone to corrosion at the heat-affected zones unless properly treated. In corrosive environments, bolting with coated fasteners may be a better choice.

- Temperature Extremes: Welding is often preferred in high-temperature applications because it eliminates the risk of bolt loosening due to thermal expansion. Conversely, bolting may be advantageous in cryogenic environments where material brittleness could compromise welded joints.

- Discussion

4.1. Key findings

The analysis highlights several critical observations regarding the cost efficiency of welding versus bolting:

- Cost Efficiency: Assembly B (bolted) demonstrated a clear cost advantage, with a total cost of €4.61 compared to €10.89 for Assembly A (welded).

- Labor Impact: Welding required significantly more labor hours, primarily due to joint preparation and inspection processes. This underscores the importance of labor availability and skill levels when selecting an assembly technique.

- Material Considerations: While welding utilized fewer raw materials, the bolted assembly’s use of pre-drilled components streamlined production and reduced setup time.

4.2. Implications for manufacturing

The findings have practical implications for manufacturers:

- Low-Volume Production: For low-volume or custom projects, bolting may be more cost-effective due to reduced labor requirements and faster assembly times.

- High-Volume Production: In high-volume scenarios, the fixed costs of pre-drilled components for bolting may outweigh the benefits, making welding a more economical choice.

- Maintenance and Reusability: Bolted assemblies offer advantages in terms of maintenance and reusability, which can lead to long-term savings in applications requiring frequent disassembly.

4.3. Limitations of the study

While the 3C tool provided valuable insights, the study has certain limitations:

- Assumptions: The analysis assumes ideal conditions, such as consistent operator skill levels and no unexpected delays.

- Long-Term Costs: The study focused on initial manufacturing costs and did not account for potential long-term savings from maintenance or reusability.

- Scaling analysis of welding and bolting costs

5.1. Introduction to scaling in assembly techniques

The choice between welding and bolting is not only influenced by the specific application but also by how costs scale with increasing seam lengths. This chapter analyzes the cost-scaling behavior of both assembly methods based on the data presented in Table II. By understanding the scaling trends, manufacturers can make informed decisions about which method is most cost-effective for different project scales.

Table 2. Price for scaling

| Seam Length (mm) | Welding Cost (€) | Number of bolts | Bolting cost (€) |

| 100 | 10.89 | 4 | 4.61 |

| 200 | 19.33 | 8 | 9.22 |

| 300 | 27.77 | 12 | 13.83 |

| 400 | 36.21 | 16 | 18.44 |

| 500 | 44.65 | 20 | 23.05 |

| 600 | 53.09 | 24 | 27.66 |

| 700 | 61.53 | 28 | 32.27 |

| 800 | 69.97 | 32 | 36.88 |

| 900 | 78.41 | 36 | 41.49 |

| 1000 | 86.85 | 40 | 46.10 |

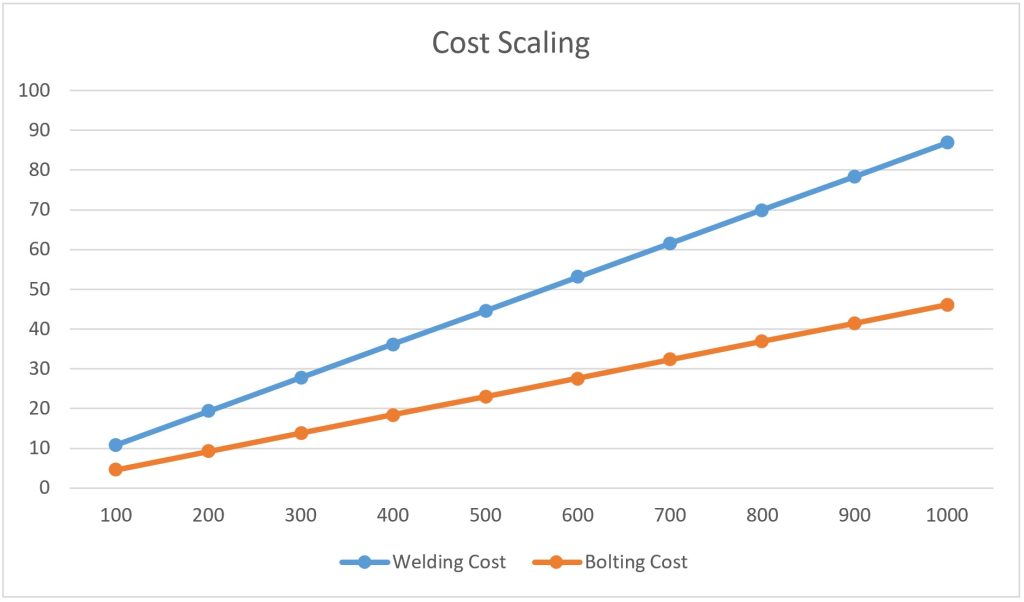

Table 2 presents the cost data associated with welding and bolting over varying seam lengths, ranging from 100 mm to 1000 mm. Each data point includes the corresponding welding cost, the number of bolts required, and the total bolting cost. This data offers valuable insight into how costs scale for both assembly methods and provides a foundation for comparing their economic efficiency at different project scales.

From the data, we observe that welding costs increase nearly linearly with seam length. At 100 mm, the cost is €10.89, and it increases by approximately €8.44 for every additional 100 mm of seam length, reaching €86.85 at 1000 mm. This trend suggests a relatively consistent cost-per-length relationship, implying that welding operations scale predictably with seam extension. This linearity can be attributed to the nature of welding, where longer seams require proportionally more time, energy, and filler material, with minimal variation in overhead for setup and tooling once the welding process begins.

In contrast, bolting costs increase in discrete steps, corresponding to the number of bolts required per seam length. For every 100 mm, four additional bolts are added, and the cost increases by about €4.61. Starting from €4.61 for 100 mm (with 4 bolts), the bolting cost reaches €46.10 for 1000 mm (with 40 bolts).

This indicates a proportional relationship between seam length and number of bolts, though the increase is more step-wise rather than smoothly linear. This is because bolts are discrete units, and their quantity scales with required structural integrity, meaning that longer seams necessitate more fasteners at regular intervals.

When comparing the two methods, it’s clear that bolting is initially more cost-effective for shorter seam lengths. At 100 mm, bolting costs €4.61 compared to €10.89 for welding—less than half. However, as seam length increases, the cost advantage of bolting narrows. At 500 mm, welding costs €44.65 while bolting costs €23.05. By 1000 mm, welding costs €86.85 and bolting €46.10. While welding remains more expensive throughout, the rate of increase is similar, keeping the cost ratio relatively steady.

This trend can be visually interpreted in Figure 3, which plots both cost curves. The welding curve is a smooth line with a constant slope, while the bolting curve appears as a stepwise line with linear progression, reflecting the discrete nature of bolt additions.

In conclusion, the scaling analysis reveals that bolting is economically preferable for small to medium-length seams, particularly where rapid assembly or disassembly is required. However, welding offers better scalability for longer, continuous seams where structural integrity, permanence, or aesthetics are prioritized. Understanding these trends helps manufacturers select the most cost-efficient method based on project size and functional requirements.

Figure 3. Cost Scaling Trends for Welding vs. Bolting

- Conclusion

This research has demonstrated the effectiveness of the 3C (Crafts Cost Calculator) as a practical and adaptable tool for estimating and comparing the costs of welding and mechanical fastening in assembly operations. By integrating real-world manufacturing parameters into a digital platform, the study provided clear, data-driven insights into the financial and operational implications of each joining method.

The comparative analysis revealed that bolted assemblies generally offer a cost advantage in terms of labor and initial setup, particularly in low-volume production and maintenance-heavy applications. Welding, while costlier in terms of labor and equipment, provides superior structural integrity and scalability for long, continuous seams and high-volume operations.

The scaling analysis further emphasized the consistent linear growth of welding costs and the stepwise increase in bolting expenses, supporting strategic decision-making based on project size. Ultimately, the findings underline the importance of early-stage cost modeling in the product design and planning process.

By using tools like the 3C, manufacturers can optimize resource allocation, reduce waste, and select the most cost-effective assembly strategy tailored to their specific technical and economic constraints. Future work may extend this model to include lifecycle cost analysis, environmental factors, and automated integration with CAD platforms, further enhancing its utility in modern manufacturing environments.

REFERENCES

Arifaj, G., Likaj, R., Berisha, B., Gjelaj, A. Dacaj, H. (2024). Product Design and Measuring Production Productivity with Conventional and CNC Machines, Journal Automation of Discrete Production, (6), 8 – 13. mf.tu-sofia.bg/mntkadp/includes/archive/2024.pdf.

Birtha, J., Marschik, C., Scherzer, T., Wolfahrt, C., Kukla, C., Kromus, A. (2023). Optimizing the process of spot welding of polycarbonate-matrix-based unidirectional thermoplastic composite tapes. Polymers, 15(9), 2182. https://doi.org/10.3390/polym15092182.

Çinay, F., Kalyon, A., Kaya, Y. (2023). Application of gray relational analysis for optimizing stud welding parameters of aluminum alloys. Proceeding of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture. https://doi.org/10.1177/09544089241298475.

Croccolo, D., De Agostinis, M., Fini, S., Yasir Khan, M., Mele, M., Olmi, G. (2023). Optimization of bolted joints: A literature review. Metals, 13(10), 1708. https://doi.org/10.3390/met13101708.

Nwodu, A., Pasha, J., Jiang, Z., Guo, W., Dulebenets, M., Wang, H., Minor, K. (2022). Co-optimisation of supply chain reconfiguration and assembly planning for factory in a box. Journal of Manufacturing Science and Engineering, 144(10), 101006. https://doi.org/10.1115/1.4054519.